ABB - Experts & Thought Leaders

White papers from ABB

Designing For Optimum Energy Management

DownloadLatest ABB Group news & announcements

A new research report from the IoT analyst firm Berg Insight says that annual shipments of wireless devices for industrial automation applications reached 10.7 million units worldwide in 2023, accounting for approximately 9 percent of all new connected nodes. Growing at a compound annual growth rate (CAGR) of 12.3 percent, annual shipments are expected to reach 19.1 million by 2028. The installed base of wireless devices in industrial automation reached at the same time 56.5 million in 2023. While wired networking solutions are still predominantly used for industrial communications between sensors, controllers and systems, wireless solutions have gained a strong foothold in a number of applications. Non-mission critical applications Wireless solutions are used in hard-to-reach locations or hazardous areas where wired solutions are impractical, ineffective or cost-prohibitive. In factory automation, wireless solutions are widely used to connect mobile industrial equipment such as automated guided vehicles and to remotely access machines for programming and servicing. In factory automation, wireless solutions are widely used to connect mobile industrial equipment In process automation, wireless technologies are increasingly used in non-mission critical applications to remotely monitor and optimise processes while also ensuring worker safety. Today, a growing number of wireless field devices are provided by many major industrial automation vendors including ABB, Emerson, Hitachi, Honeywell, OMRON, Schneider Electric, Siemens and Yokogawa. Remote monitoring applications Wi-Fi has emerged as the most widely used wireless technology in industrial environments largely due to the wide availability of compatible hardware. Providers of industrial Wi-Fi devices include Siemens, Cisco, Belden, Moxa, Phoenix Contact, HMS Networks and Advantech. The 802.15.4-based protocol WirelessHART is the second largest wireless technology used in field devices. The technology is widespread in remote monitoring applications for process industries. Emerson became the first company to market WirelessHART products in 2008 and has today an installed base of more than 10 million wireless pressure transmitters. Industrial automation market Cellular solutions are typically used for data acquisition and backhaul communications Cellular solutions are typically used for data acquisition and backhaul communications in distributed automation applications. The largest providers of cellular IoT gateways and routers in the industrial space include Semtech, Cisco, Digi International, Moxa, GE Vernova, HMS Networks, Robustel, InHand Networks and Teltonika Networks. Devices featuring Wi-Fi, WirelessHART and cellular connectivity accounted for 70 percent of the installed base in 2023. “Partnerships and collaborations between industrial automation players and technology companies are increasingly focused on artificial intelligence,” said Veronika Barta, IoT Analyst at Berg Insight. During 2023–2024, the industrial automation market witnessed both the emergence of new partnerships as well as the extension of existing collaborations focusing on AI. AI-powered industrial solutions For instance, both ABB and Siemens extended their respective partnerships with Microsoft to focus on generative AI applications in digital solutions. In addition, both Schneider Electric and Siemens have partnerships with NVIDIA to advance the use of AI-powered industrial solutions. Most recently in June 2024, Rockwell Automation announced a collaboration with NVIDIA to scale the use of AI in industrial mobile robots. “More collaborations and partnerships can be expected in the coming years as solution providers bet on AI to optimise industrial processes,” concluded Ms. Barta.

A collaboration between ABB and Arkitech has brought significant efficiency gains for the heating, ventilation, and air-conditioning (HVAC) system on board MSC Magnifica. Using artificial intelligence and machine learning to analyze data from over 1,500 sensors on the MSC Cruises ship, this technology enables up to 12 percent increase in chiller efficiency to achieve monthly energy savings of 100 MW by the 15-year-old ship, while maintaining optimal air-handling unit performance. energy efficiency The HVAC systems onboard cruise ships and ferries are often one of the largest energy consumers after propulsion, making energy efficiency a priority. The ABB solution based on ARK-M20 is designed to minimize the cost and environmental impact of this system. It works by continuously optimizing the HVAC system’s temperature set point in response to variable conditions including weather, seawater temperature, mobility, proportion of passenger capacity filled, time of day, and position in port or at sea. emissions savings "Controlling the most energy-demanding processes onboard – propulsion, hotel operations, and HVAC – is increasingly important," said Ivana Melillo, Head of Energy Efficiency, MSC Cruise Management (UK) Limited. Ivana Melillo adds, "Reducing energy needs can decrease fuel consumption and emissions. Thanks to the project, we expect to save 10-12 percent of HVAC energy consumption, equating to nearly 1 ton of fuel saved daily. The greatest emissions savings come from the fuel we don't use." operational improvements and sustainability "As maritime organizations seek to enhance operational efficiency and reduce their carbon footprint, innovative technologies like ARK-M20 are well positioned to support this growing demand," said Alessandro De Santis, Manager – Service Area South Europe, ABB Marine & Ports. Alessandro De Santis adds, "Our collaboration with Arkitech and MSC Cruises emphasizes our commitment to delivering measurable energy savings and operational improvements through technology. The project’s success is yet another testament to our leadership in advancing efficiency and sustainability in the maritime industry." ARK-M20 system Supplied in a modular plug-and-play configuration, the ARK-M20 system can be installed seamlessly Supplied in a modular plug-and-play configuration, the ARK-M20 system can be installed seamlessly during normal vessel operations to offer a platform to monitor vessel air quality. As well as providing a safe and comfortable environment for passengers and crew, optimizing HVAC performance contributes towards compliance with regulations such as the International Maritime Organization’s Carbon Intensity Indicator. energy savings of 100 MW per month "The results achieved by our ARK-M20 system onboard MSC Magnifica exceeded our initial target, equating to energy savings of 100 MW per month and an anticipated 1,600–2,000 MW per year," said Sander Huijer, Chief Executive Officer, Arkitech. Sander Huijer adds, "We are grateful to ABB for its support, in a project which demonstrates the efficiency gains, cost savings, and emissions reduction, which can be achieved without compromising performance or guest and crew comfort."

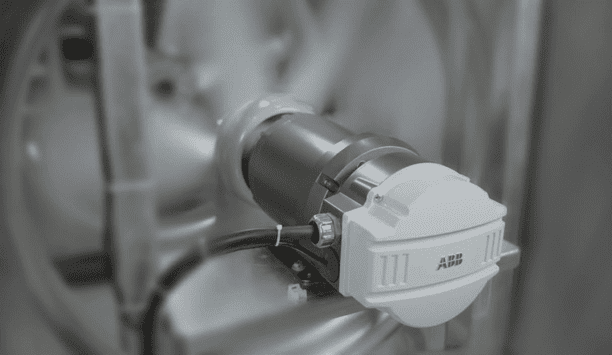

To support refrigeration OEMs in their green transition, ABB has successfully tested its key refrigeration drives to assure conformity with safety standards, when using the new A2L and A3 refrigerants. This means that surface temperatures in the specified drives – HVACR ACH180 and ACH580, General Purpose ACS580 and Machinery ACS180 – have now been examined and found to be within safe limits, as described in the standard, and no arcs or sparks are produced during operation in normal conditions. IEC/UL 60335-2-40 safety standard Therefore, according to the IEC/UL 60335-2-40 testing standard, the drives are not considered a potential source of ignition when working near A2L or A3 classified refrigerants. The IEC/UL 60335-2-40 safety standard covers the safety of 'Household and similar electrical appliances', including electrical heat pumps, air-conditioners, and dehumidifiers. It involves various safety requirements, including protection against electric shock, fire hazards, and mechanical hazards. Extra parts improve safety and OEMs likely cost reductions In addition, multiple other features, both standard and options, can be used to reduce As a further benefit, the ACH and ACS range of products includes STO (safe torque off) inputs, reducing the need to use external safety relays in safety-critical systems. In addition, multiple other features, both standard and options, can be used to reduce the overall system cost even more. This is good news for OEMs, their customers and end users, who can confidently use and rely on the ABB drives when working near modern refrigeration equipment. This gives the key benefits of increasing energy efficiency, and reducing integration costs, without unnecessary concern about ignition safety, thus enabling the green transition. Compliance as a priority Stefano Ghidella, ABB’s Global Business Development Manager for refrigeration drives, explains why ABB went through the conformity process. Stefano Ghidella said, “Drives play a critical role in ensuring safety in machinery operating with A2L and A3 refrigerants. And the A2L/A3 refrigerants are rapidly gaining market share thanks to their low greenhouse gas intensity and lower toxicity compared to other materials. That’s why we made this conformity a priority. Now OEMs don’t need to worry about their drives as a potential ignition source or safety hazard.” IEC/UL 60335-2-40 safety standard for A2L and A3 refrigerants ABB is one of just a few known drive suppliers that declares conformity to IEC/UL 60335-2-40 safety standard for A2L and A3 refrigerants, which gives advantages for both ABB and its customers. With this Declaration of Conformity, machine builders and their customers working with commercial and residential buildings, data centers, supermarkets, food manufacturing, and many other sectors can be assured that their heating or cooling/refrigeration systems are meeting the highest standards, safely. Declaration of Conformity documents More details can be found in this Declaration of Conformity documents: A3 ACH180/ACS180 ABB Library - 3AXD100002137757 A3 ACH580/ACS580/ACQ580 ABB Library - 3AXD10002137760 A2L ACH180 ABB Library - 3AXD10002047577 A2L ACH580/ACS580/ACQ580 ABB Library - 3AXD10002047587 A2L ACS180 ABB Library - 3AXD10002158560

Insights & Opinions from thought leaders at ABB

The COVID-19 pandemic has significantly impacted how we view indoor air quality and HVAC systems. Consequently, HVAC systems have undergone several improvements in the post-pandemic world. Systems today tend to have better filtration, increased ventilation, and advanced air-cleaning technologies, such as UV-C light and bipolar ionization. We asked our Expert Panel Roundtable: How have HVAC systems improved (including better indoor air quality) in the post-pandemic world?

Achieving net-zero emissions will mitigate climate change and prevent the worst impacts of global warming. Net zero is the state in which the total amount of greenhouse gases emitted into the atmosphere is equal to the total amount removed. HVAC systems represent a large opportunity to impact how soon we can achieve net zero. We asked our Expert Panel Roundtable: What is the role of HVAC in achieving net-zero emissions by 2050?

Digitalization is the integration of digital technologies into everyday life. In the context of HVAC, digitalization refers to the use of digital technologies to improve the efficiency, performance, and control of heating, ventilation, and air conditioning systems. Considering that digitalization is a major trend relating to HVAC, we asked our Expert Panel Roundtable: How does the digitalization of HVAC enable adaptation to evolving technologies and newer applications?

Leveraging Radiant And Hydronics To Help Achieve Decarbonization Goals

DownloadSealed Connectors In Harsh Environments

DownloadPowering And Cooling Next Generation Data Centers

DownloadDebunking Myths To Promote A Bright Future For Heat Pumps

DownloadOptimizing Comfort: The Ultimate HVAC Component Guide

Download