Capacity

As demand continues to grow for sustainable, energy-efficient solutions in refrigeration and heating, both Europe and North America are navigating a rapid transition toward natural refrigerants. There is a strong demand for new CO2 systems, including heat pumps and various other applications. Higher capacity compressors with larger operating envelope, such as Danfoss’ Bock HGX56 CO2 T series, will play a critical role in supporting this growing need. Air to water heat pumps As shown in...

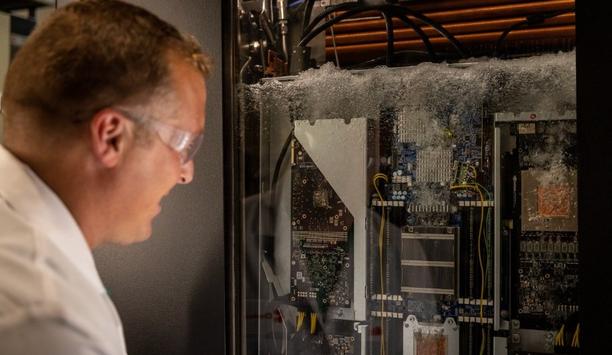

Modern data centers require advanced cooling solutions to operate at peak performance. As one of the most rapidly growing industries in the world, data centers are changing how they develop new cooling technology at a record pace. The data center market is projected to continue growing by 8.5% per year over the next five years, to over $600 billion by 2029. Global power demand by 2028 Artificial intelligence (AI) and machine learning (ML) are driving increased data center demand, and the...

A survey conducted by Baxi of 200 state school estate managers, consultant engineers, and M&E contractors has found that while enthusiasm for net zero and support for low-carbon heating systems in schools is thriving, persistent barriers remain. The survey found extremely strong support for net zero within schools, with 90% of estates managers who responded agreeing that net zero is a priority, a sentiment echoed by 78% of consultant engineers and contractors. 99% of the school estate manag...

Viessmann Climate Solutions (VCS) has combined with Carrier to become the core of Carrier’s newly formed business unit Residential and Light Commercial for European, Middle East and Africa. This business unit is now able to offer brands like Carrier, Toshiba, and Beretta next to the premium brand Viessmann, thus covering additional user segments with differentiated products at various price points. Climate system technology “The climate system technology of Viessmann Climate Solu...

Does anyone still think that heat pump technologies for residential applications are ineffective in cold climates? If so, they are missing opportunities available through advancements in heat pump technology. New developments in heat pumps are significantly transforming the residential HVAC market. These advanced heat pumps can maintain 100% heating capacity at 0 degrees F and operate efficiently at low temperatures. Secondary heat sources These capabilities reduce the need for secondary hea...

Two Tyneham 290HT 27kW air source heat pumps from Hamworthy Heating – a trusted British manufacturer and supplier of commercial heating and hot water products – have been installed in cascade for underfloor heating in a new extension at a primary school in Cambridge. To accurately meet the heating requirements of the new school extension and ensure an even distribution of heat, the new system from Hamworthy Heating includes two 290HT 27kW Tyneham heat pumps with natural refrigerant,...

News

A-Gas, a world pioneer in environmentally responsible lifecycle refrigerant and fire suppressant management, acquired Refrigerant Services Inc. (RSI), a recognized brand in the Canadian refrigerant industry. The acquisition, finalized in late March 2025, further solidifies A-Gas' position as a world pioneer in the supply and lifecycle management of refrigerants and associated products and services. Strengthening Commitment It ensures that customers receive the maximum value and benefit of lifecycle refrigerant management This acquisition aligns with A-Gas' commitment to delivering enhanced refrigerant solutions and support to businesses across North America. It also ensures that customers in the Canadian market receive the maximum value and benefit of lifecycle refrigerant management while maintaining access to a full range of products and services. "We are thrilled to welcome Refrigerant Services Inc. to A-Gas," said Mike Armstrong, Managing Director and President of A-Gas in the Americas. “We are excited to continue serving the Canadian market, combining our expertise to provide circular solutions in the refrigerant industry with RSI’s over thirty years of exceptional customer service and dedication to the Canadian market. We look forward to delivering the same dedication and expertise that has defined both companies." Strengthening Innovation "We are excited to join forces with A-Gas, as their global expertise and resources will significantly enhance our ability to serve the Canadian market," said Jim Thomas , President of Refrigerant Services Inc. "Together, we will continue to innovate and provide environmentally responsible refrigerant management solutions that meet the evolving needs of our customers." Enhanced Refrigerant Solutions Both companies' merger and brands will remain intact, ensuring continuity and familiarity for existing customers. This strategic move allows A-Gas to leverage the strengths of both organizations, combining their expertise to better serve the evolving needs of the Canadian refrigerant market. A-Gas, with the support of its co-investors TPG Rise Climate and KKR, continues to strengthen its position as a world pioneer in the supply and lifecycle management of refrigerants and associated products and services. With this latest acquisition, A-Gas is poised to deliver enhanced solutions and support to businesses across Canada, furthering its goal of promoting environmentally conscious and circular practices in the refrigerant industry. Expert Consultancy A-Gas received legal advisory services from Stikeman Elliott LLP, financial advisory services from PricewaterhouseCoopers LLP and environmental support from Stantec Consulting Ltd.

Trane Technologies a global climate innovator, is revolutionizing mission critical operations with the development of two new air-cooled chiller offerings – Magnetic Bearing chillers and Ascend chillers for facility chilled water-cooling applications. Trane’s Magnetic Bearing Chiller provides unparalleled cooling capacity to address the escalating capacity needs of data center thermal management systems. Introduction of the Ascend chiller platform for data centers provides even greater efficiency for high ambient temperature operations. Advanced Thermal Solutions “Next-gen microprocessors are expected to exponentially increase rack density, elevating demand for efficient, higher capacity and higher ambient air-cooled chillers,” said Steve Obstein, Vice President and General Manager, Data Centers & High-Tech, Trane Technologies. “Building on our leading platforms, in close collaboration with our customers, gives us the ability to redefine the standards of cooling efficiency, capacity, and environmental sustainability for data center owners and operators, helping them stay ahead of rapidly advancing thermal management needs.” Maximize Cooling Capacity with a Reduced Footprint The new chiller helps maximize cooling capacity per square foot of unit footprint The new air-cooled chiller, based on Trane’s proven Magnetic Bearing compressor platform, produces up to 850 tons, 3MW at data center conditions on a single unit frame. The new chiller helps maximize cooling capacity per square foot of unit footprint, often allowing for a reduction in the number of chillers needed onsite and helping to enable lower installation costs. Replacing multiple chillers with a single larger capacity chiller can help reduce sound transmission to the local environment, helping reduce the impact in sound sensitive locations. Higher Ambient Temperature Operations Through the extended capabilities of the Ascend screw-compressor chiller platform, Trane is leading with solutions that meet customer needs to address escalating ambient temperatures from greater heat density generated by modern GPUs and AI adoption. Expansion of the Trane Ascend Air-Cooled Chiller with integrated indirect free cooling, supports data center uptime with efficient operation at up to 145F. Free cooling reduces reliance on mechanical cooling, and helps reduce energy consumption and operational costs. Designed for Higher Efficiency and Serviceability The new air-cooled chillers use refrigerants with lower global warming potential, supporting reduced energy costs and carbon footprints. Both chillers are equipped with Trane’s Symbio 800 unit controller with AdaptiView user interface, offering secure enhanced connectivity, flexibility, and serviceability. Trane supports operations and uptime throughout the lifecycle of the data center with thousands of local service experts across North America, strategically located in proximity to customers, and Smart Service options for proactive monitoring, predictive maintenance, and improved thermal management systems.

Pfannenberg, Inc., a pioneering manufacturer of thermal management and signaling technologies, proudly announces the DHS Hybrid Series (DHS 34X1). By combining free cooling with active cooling, this closed-loop system safeguards critical electronics within an enclosure while lowering energy consumption, cutting costs, and reducing carbon emissions. Free cooling with active cooling DHS-Series achieves its optimal efficiency by combining free cooling with active cooling “The DHS-Series combines the best of free cooling and active cooling to radically impact an end-user's energy consumption and carbon emissions while cooling their critical electronics,” says James Wong, Pfannenberg’s Director of Global NEMA Product Management. The DHS-Series achieves its optimal efficiency by combining free cooling with active cooling. Free cooling is a technology that minimizes energy use by using the cooler air outside the enclosure to remove heat from inside the enclosure. Efficiency of the cooling unit Active cooling utilizes a compressor and refrigerant cycle to cool the air in the enclosure when it exceeds the desired temperature of the enclosure. This combination optimizes the efficiency of the cooling unit, thereby reducing energy usage. This dual system also provides redundancy in a single unit to avoid downtime, fits all full-sized enclosures, and also features an easy-to-read status display. Warehouse automation The product proves ideal for locations with lower ambient temperatures The DHS-Series is offered in indoor (Type 12), outdoor (Type 3R/4), and in washdown (Type 4X) configurations. The product proves ideal for locations with lower ambient temperatures, climate-controlled facilities, and operations that periodically run at partial capacity. This can include everything from automotive manufacturing and warehouse automation to outdoor facilities and food and beverage manufacturing. DHS-Series UL 60335 standard The DHS-Series meets high standards for electrical safety, being certified to the UL 60335 standard. Additionally, the hybrid cooler is pre-gasketed to make installation even easier. The product has also been designed to meet upcoming environmental regulations governing the use of the R-513A refrigerant.

Quilt, a pioneering innovator in smart home climate technology, announced that Matt Rogers, CEO and co-founder of Mill, co-founder of Nest, and founder of Incite, has joined its board of directors. A prominent figure in the smart home, design, and climate space, Rogers is widely respected for creating the iconic smart thermostat and for accelerating growth for mission-driven organizations. Quilt's growth and innovation Quilt, Nest and Mill are among the most successful startups in the smart home space, and Rogersʼ deep expertise in product development, business scaling, and partnership building will be instrumental in driving Quilt's continued growth and innovation. Since launching in the Bay Area in May 2024, Quilt has quickly emerged as an industry pioneer, selling through its entire 2024 installation capacity shortly after its debut, and earning Energy Star recognition as the most efficient two-zone heat pump on the market. Adoption of smart home technology Quilt is poised to roll out industry-defining features and will expand its extreme smart heat pump Following such exceptional demand and recognition, Quilt is poised to roll out industry-defining features and will expand its revolutionary smart heat pump to new markets across the country in 2025. Rogersʼ appointment underscores the growing mainstream adoption of smart home technology, with intuitive and elegantly designed systems like Quilt heralding a future where sustainable living is both responsible and highly desirable. Modern home comfort to new markets "Matt has been an invaluable advisor to Quilt since our earliest days, and we are thrilled to officially welcome him to our board," said Paul Lambert, CEO of Quilt. "His deep industry expertise, proven business acumen, and collaborative spirit will be instrumental as we scale and bring our vision for modern home comfort to new markets nationwide." Incredible technology and people-centric approach “Quilt has developed technology that will change what is possible with smart climate control inside our homes. It gives people the ability to manage heating and cooling in a way thatʼs intuitive, effortless and cost-effective. Not only is this a better experience in your home, itʼs better for the planet too." "I love this combination of incredible technology and a people-centric approach. I am excited to join the board and continue to support Quiltʼs vision for the future,ˮ Matt Rogers, CEO, Co-Founder of Mill and Founder of Incite.

The Plumbing and Heating Federation (SNIPEF) has raised concerns that the Scottish Government’s announcement on a revised Heat in Buildings Bill failed to address the core challenge of how decarbonization will be delivered, with no mention of workforce skills, installer training or targeted support for small and medium-sized businesses (SME’s). This support is crucial, as 80% of heat pump installations are expected to be completed by SME’s. How Scotland will develop the skilled workforce While welcoming the move to more realistic long-term targets and a renewed focus on fuel poverty, SNIPEF said the announcement lacked critical detail on how Scotland will develop the skilled workforce and business capacity required to install low-carbon heating at scale. Fiona Hodgson, Chief Executive of SNIPEF, said: “We support the Government’s intention to move away from immediate restrictions on homeowners and instead focus on national targets. That change of tone is constructive and gives the plumbing and heating profession a clearer signal on the direction of travel." Rising apprenticeship costs SNIPEF represents over 700 member firms using more than 3,500 plumbing and heating experts Hodgson added: “But today’s announcement is silent on how the work will actually get done. There is no reference to skills, vocational training or business support; yet these are the foundations on which success depends. Without them, we risk setting targets that are simply undeliverable.” SNIPEF, which represents over 700 member firms employing more than 3,500 plumbing and heating professionals, also highlighted the financial strain facing smaller businesses, particularly in relation to rising apprenticeship costs following the significant increase in minimum apprentice wage rates. Policy measures The Federation is calling on the Scottish Government to ensure that the forthcoming Bill and accompanying policy measures include: Dedicated and accessible funding for SMEs to support upskilling and investment in low-carbon technologies Increased investment in apprenticeships and vocational education to grow a future-ready workforce Clear, stable policy direction that enables businesses to plan and invest with confidence. Skills, training, and SME capacity “Around 80% of our members still work in the traditional heating market,” Hodgson added. “They are willing to play a key role in Scotland’s transition, but they can’t do that without practical support. Skills, training and SME capacity must be at the heart of the next stage." “Apprenticeship funding has remained stagnant for over eight years, placing additional financial strain on small businesses already managing rising employer National Insurance contributions, increased minimum wage rates and growing operational costs. These pressures are real, and without targeted intervention, they risk choking off the very workforce we need to deliver change.”

The power grid is undergoing a transformation to keep pace with the rising energy demands of our modern era. This shift is driven by major trends such as the electrification of transportation and HVAC systems, as well as the rapid expansion of AI and renewable energy. Smart Grid The goal is to evolve the traditional electric infrastructure into a more advanced To enhance capacity, resilience, and adaptability, the goal is to evolve the traditional electric infrastructure into a more advanced "Smart Grid." This modernization takes inspiration from Industry 4.0, which leverages tools such as sensors, IoT, and data analytics, to revolutionize operational efficiency across all sectors of the economy. The cornerstone of this digital ecosystem is the intelligence it brings to grid operations, offering valuable insights and actionable data. It enables real-time asset health monitoring and supports proactive, condition-based maintenance. By identifying potential issues early, operators can implement predictive strategies—such as refilling gas or replacing O-rings—before failures occur. This condition-driven approach addresses problems based on the actual state of equipment, reducing the risk of unexpected breakdowns, lowering the need for expensive emergency repairs, and extending the lifespan of critical, high-value assets. The Role of Advanced Gas Density Sensors A key enabler of this transformation is the adoption of advanced gas density sensors in gas-insulated switchgear (GIS). Since the 1980s, GIS has become widely popular due to its compact design, excellent reliability, and ability to handle higher voltage levels efficiently. High-voltage switchgear has evolved significantly—from the bulky air-insulated switchgear (AIS), which occupied the size of a football field, to GIS systems that require just 10% of that space. This innovation is possible thanks to pressurized chambers filled with highly compressed insulating gas, which house the high-voltage components. This gas effectively prevents or extinguishes arc faults and short circuits, enabling more reliable and space-saving power systems. Critical Gas Density Sulfur hexafluoride is the most effective gas for insulation and arc extinguishing at high voltages Sulfur hexafluoride is the most effective gas for insulation and arc extinguishing at high and extra-high voltages. However, SF6 has a greenhouse gas effect 23,500 times greater than CO2, making even small leaks unacceptable. For this reason, strict regulations worldwide demand rigorous monitoring to prevent SF6 from escaping. Effectively monitoring insulating gas density is more critical than ever for ensuring the reliability and safety of gas-insulated high-voltage systems. Maintaining proper gas density within pressure compartments is essential to prevent functionality issues, safety risks, and environmental violations caused by leaks. This is also critical as the industry explores less environmentally harmful alternatives to SF6, which still require precise monitoring to ensure sufficient insulating gas levels are maintained. Predictive Maintenance Utilities now face dual challenges: operating plants without interruptions and reducing plant sizes. This has led to a shift toward continuous electronic density monitoring and predictive maintenance over traditional warning and shutdown systems. As smaller compartments with reduced insulation volumes become the norm, tighter gas monitoring is essential. Traditional Gas Density Monitoring Pressure gauges, using Bourdon tubes and bimetallic temperature compensation, were once standard for monitoring systems. While cost-effective, they are less precise due to design limitations. Gas density is typically inferred from pressure using manometers or sensors, but significant temperature variations in closed systems lead to inaccuracies without proper compensation. In a closed, gas-insulated system, the number of gas molecules (density) remains constant, but pressure and temperature vary based on isochores. Outdoor installations face temperature extremes from -40°C to +60°C, requiring precise temperature compensation to avoid false readings. Without this, sunlight or frost can cause density displays to fluctuate, even when the actual gas density remains unchanged. Extreme Condition Challenges Outdoor installations are an increasing share of gas-insulated switchgear (GIS) setups due to the rapid growth of renewable energy projects and the rising need to support bulk power transfers across long distances. Bimetallic temperature compensation must be tailored to the insulating gas, but large temperature fluctuations can lead to significant measurement inaccuracies. At extreme temperatures, these inaccuracies increase further, resulting in false alarms. Reliable gas density monitors must withstand harsh conditions, function across varying altitudes and pressures, and ensure continuous, accurate measurements. Breakthrough in Accuracy Traditional temperature-compensated pressure gauges fell short when it came to reliable gas density monitoring, often lacking the precision needed and leading to false alarms. To address this, Trafag AG, in collaboration with switchgear manufacturers, revolutionized the field in 1987 with the introduction of an innovative reference chamber system. This advancement significantly outperformed conventional manometer-based designs, offering greater accuracy and reducing the occurrence of false alerts. Unlike conventional density gauges, Trafag’s system uses a reference gas housed in an isolated reference chamber. This reference gas mirrors the properties of the insulation gas within switchgear components. Both gases are thermally coupled, maintaining identical temperatures, which eliminates pressure variations caused by temperature changes. By design, the monitors are fully temperature-compensated, delivering a level of accuracy that surpasses standard pressure gauges. Why Accuracy Matters When insulation gas pressure drops, the reference chamber system activates precise mechanical switching points via microswitches. At the first alarm level, operators are prompted to refill the insulation gas. Only a rapid and significant pressure loss triggers an automatic system shutdown, thanks to the system’s reliable secondary switching points. This high level of accuracy has significant benefits. Density monitors designed with narrow alarm thresholds enable more compact and efficient plant designs. With greater measurement precision, insulation volumes can be reduced, allowing for smaller, optimized systems. This minimizes the site area required for switchgear installations. In contrast, less accurate density monitoring necessitates larger volumes and broader tolerances, resulting in bulkier, less efficient designs. Continuous Monitoring Gas monitors have improved measurement accuracy by reducing temperature distortions Gas monitors with reference chamber designs have significantly improved measurement accuracy by reducing temperature-related distortions. But these systems have inherent limitations. They only provide precise readings at specific moments, triggered when pressure crosses a microswitch threshold, providing only intermittent data points. This limitation leaves gaps in system visibility, requiring engineers to rely on data interpolation or trend extrapolation to evaluate and predict system performance. As the power distribution industry increasingly relies on real-time, high-resolution data for advanced analytics and preventative maintenance, the need for continuous monitoring has become crucial. To address this challenge, a significant breakthrough emerged in the mid-1990s with the introduction of Trafag's electronic density sensor. Accurate Gas Measurement This innovation utilized quartz tuning fork technology—a method commonly used in timekeeping devices—to enable continuous, drift-free gas density measurement. By measuring changes in resonant frequency as the tuning fork oscillates within the gas, this technology provides continuous, real-time monitoring. The density sensors are mounted to the pressure compartment via a customizable process connection, ensuring equilibrium between the insulating gas in the compartment and the sensor's measurement chamber. The system uses two quartz oscillators: one in a vacuum and the other surrounded by the insulating gas. By comparing their resonant frequencies, the sensor determines the gas density with exceptional accuracy. Density Detection Gases of different densities alter the predetermined resonant frequency of the quartz tuning fork surrounded by the process gas. This shift in frequency is proportional to the gas density, with a response time of less than 10 milliseconds—ideal for detecting rapid density changes. Additionally, a built-in temperature sensor refines the measurement for even greater reliability. Condition-Based Preventive Maintenance Digital gas density sensors with continuous monitoring capabilities enable the shift from traditional time-based preventive maintenance to a more efficient, condition-driven approach. Time-Based Maintenance: Maintenance has traditionally been scheduled based on factors such as material aging and the environmental conditions in which equipment operates. This approach aims to prevent failures by servicing or replacing parts at set intervals. However, it often leads to unnecessary replacements and increased costs, as components may not always require maintenance when scheduled. Efficient Upkeep Condition-Based Maintenance: In contrast, condition-based maintenance is based on the actual, real-time state of the equipment. By monitoring the condition of components, this strategy identifies which parts require attention, allowing operators to perform maintenance only when wear or degradation is detected. This targeted approach not only reduces unnecessary downtime but also extends the lifespan of components by addressing issues before they escalate into major failures. It represents a more efficient and cost-effective way to manage equipment. Predictive Insights With the implementation of continuous monitoring, operators gain a comprehensive and accurate understanding of the gas's current state and its evolution over time. The sensors provide high resolution data that can be analyzed to spot trends, enabling predictive maintenance and more informed decision-making. Preparing for the Future The shift toward a smarter, more intelligent grid, coupled with condition-based maintenance, represents a gradual evolution rather than a sudden revolution. This transformation takes time, and systems are adapting at different speeds. However, even those in the early stages of this transition can recognize the direction the industry is heading. Given that gas-insulated switchgear typically has a lifespan of 30-40 years or more, it is prudent to future-proof infrastructure. As a result, some are turning to hybrid systems. The hybrid gas density monitor combines the advantages of a mechanical monitor with a reference gas chamber and the advanced functionalities of an electronic gas density sensor, all integrated into a compact, multi-functional device. With continuous measurement output, it is ideally suited for gas management and trend analysis systems. It also includes a local display and durable switchpoint alarm contacts for enhanced reliability. Smart Grid Integration Even if the current digital ecosystem is not fully equipped to utilize the continuous monitoring and real-time data provided by the electronic gas sensor, this technology is seamlessly embedded within the equipment. This ensures its availability for future use as grids evolve and become more compatible with smart technologies.

A-Gas, a world pioneer in environmentally responsible lifecycle refrigerant and fire suppressant management, acquired Refrigerant Services Inc. (RSI), a recognized brand in the Canadian refrigerant industry. The acquisition, finalized in late March 2025, further solidifies A-Gas' position as a world pioneer in the supply and lifecycle management of refrigerants and associated products and services. Strengthening Commitment It ensures that customers receive the maximum value and benefit of lifecycle refrigerant management This acquisition aligns with A-Gas' commitment to delivering enhanced refrigerant solutions and support to businesses across North America. It also ensures that customers in the Canadian market receive the maximum value and benefit of lifecycle refrigerant management while maintaining access to a full range of products and services. "We are thrilled to welcome Refrigerant Services Inc. to A-Gas," said Mike Armstrong, Managing Director and President of A-Gas in the Americas. “We are excited to continue serving the Canadian market, combining our expertise to provide circular solutions in the refrigerant industry with RSI’s over thirty years of exceptional customer service and dedication to the Canadian market. We look forward to delivering the same dedication and expertise that has defined both companies." Strengthening Innovation "We are excited to join forces with A-Gas, as their global expertise and resources will significantly enhance our ability to serve the Canadian market," said Jim Thomas , President of Refrigerant Services Inc. "Together, we will continue to innovate and provide environmentally responsible refrigerant management solutions that meet the evolving needs of our customers." Enhanced Refrigerant Solutions Both companies' merger and brands will remain intact, ensuring continuity and familiarity for existing customers. This strategic move allows A-Gas to leverage the strengths of both organizations, combining their expertise to better serve the evolving needs of the Canadian refrigerant market. A-Gas, with the support of its co-investors TPG Rise Climate and KKR, continues to strengthen its position as a world pioneer in the supply and lifecycle management of refrigerants and associated products and services. With this latest acquisition, A-Gas is poised to deliver enhanced solutions and support to businesses across Canada, furthering its goal of promoting environmentally conscious and circular practices in the refrigerant industry. Expert Consultancy A-Gas received legal advisory services from Stikeman Elliott LLP, financial advisory services from PricewaterhouseCoopers LLP and environmental support from Stantec Consulting Ltd.

Trane Technologies a global climate innovator, is revolutionizing mission critical operations with the development of two new air-cooled chiller offerings – Magnetic Bearing chillers and Ascend chillers for facility chilled water-cooling applications. Trane’s Magnetic Bearing Chiller provides unparalleled cooling capacity to address the escalating capacity needs of data center thermal management systems. Introduction of the Ascend chiller platform for data centers provides even greater efficiency for high ambient temperature operations. Advanced Thermal Solutions “Next-gen microprocessors are expected to exponentially increase rack density, elevating demand for efficient, higher capacity and higher ambient air-cooled chillers,” said Steve Obstein, Vice President and General Manager, Data Centers & High-Tech, Trane Technologies. “Building on our leading platforms, in close collaboration with our customers, gives us the ability to redefine the standards of cooling efficiency, capacity, and environmental sustainability for data center owners and operators, helping them stay ahead of rapidly advancing thermal management needs.” Maximize Cooling Capacity with a Reduced Footprint The new chiller helps maximize cooling capacity per square foot of unit footprint The new air-cooled chiller, based on Trane’s proven Magnetic Bearing compressor platform, produces up to 850 tons, 3MW at data center conditions on a single unit frame. The new chiller helps maximize cooling capacity per square foot of unit footprint, often allowing for a reduction in the number of chillers needed onsite and helping to enable lower installation costs. Replacing multiple chillers with a single larger capacity chiller can help reduce sound transmission to the local environment, helping reduce the impact in sound sensitive locations. Higher Ambient Temperature Operations Through the extended capabilities of the Ascend screw-compressor chiller platform, Trane is leading with solutions that meet customer needs to address escalating ambient temperatures from greater heat density generated by modern GPUs and AI adoption. Expansion of the Trane Ascend Air-Cooled Chiller with integrated indirect free cooling, supports data center uptime with efficient operation at up to 145F. Free cooling reduces reliance on mechanical cooling, and helps reduce energy consumption and operational costs. Designed for Higher Efficiency and Serviceability The new air-cooled chillers use refrigerants with lower global warming potential, supporting reduced energy costs and carbon footprints. Both chillers are equipped with Trane’s Symbio 800 unit controller with AdaptiView user interface, offering secure enhanced connectivity, flexibility, and serviceability. Trane supports operations and uptime throughout the lifecycle of the data center with thousands of local service experts across North America, strategically located in proximity to customers, and Smart Service options for proactive monitoring, predictive maintenance, and improved thermal management systems.

Pfannenberg, Inc., a pioneering manufacturer of thermal management and signaling technologies, proudly announces the DHS Hybrid Series (DHS 34X1). By combining free cooling with active cooling, this closed-loop system safeguards critical electronics within an enclosure while lowering energy consumption, cutting costs, and reducing carbon emissions. Free cooling with active cooling DHS-Series achieves its optimal efficiency by combining free cooling with active cooling “The DHS-Series combines the best of free cooling and active cooling to radically impact an end-user's energy consumption and carbon emissions while cooling their critical electronics,” says James Wong, Pfannenberg’s Director of Global NEMA Product Management. The DHS-Series achieves its optimal efficiency by combining free cooling with active cooling. Free cooling is a technology that minimizes energy use by using the cooler air outside the enclosure to remove heat from inside the enclosure. Efficiency of the cooling unit Active cooling utilizes a compressor and refrigerant cycle to cool the air in the enclosure when it exceeds the desired temperature of the enclosure. This combination optimizes the efficiency of the cooling unit, thereby reducing energy usage. This dual system also provides redundancy in a single unit to avoid downtime, fits all full-sized enclosures, and also features an easy-to-read status display. Warehouse automation The product proves ideal for locations with lower ambient temperatures The DHS-Series is offered in indoor (Type 12), outdoor (Type 3R/4), and in washdown (Type 4X) configurations. The product proves ideal for locations with lower ambient temperatures, climate-controlled facilities, and operations that periodically run at partial capacity. This can include everything from automotive manufacturing and warehouse automation to outdoor facilities and food and beverage manufacturing. DHS-Series UL 60335 standard The DHS-Series meets high standards for electrical safety, being certified to the UL 60335 standard. Additionally, the hybrid cooler is pre-gasketed to make installation even easier. The product has also been designed to meet upcoming environmental regulations governing the use of the R-513A refrigerant.

Quilt, a pioneering innovator in smart home climate technology, announced that Matt Rogers, CEO and co-founder of Mill, co-founder of Nest, and founder of Incite, has joined its board of directors. A prominent figure in the smart home, design, and climate space, Rogers is widely respected for creating the iconic smart thermostat and for accelerating growth for mission-driven organizations. Quilt's growth and innovation Quilt, Nest and Mill are among the most successful startups in the smart home space, and Rogersʼ deep expertise in product development, business scaling, and partnership building will be instrumental in driving Quilt's continued growth and innovation. Since launching in the Bay Area in May 2024, Quilt has quickly emerged as an industry pioneer, selling through its entire 2024 installation capacity shortly after its debut, and earning Energy Star recognition as the most efficient two-zone heat pump on the market. Adoption of smart home technology Quilt is poised to roll out industry-defining features and will expand its extreme smart heat pump Following such exceptional demand and recognition, Quilt is poised to roll out industry-defining features and will expand its revolutionary smart heat pump to new markets across the country in 2025. Rogersʼ appointment underscores the growing mainstream adoption of smart home technology, with intuitive and elegantly designed systems like Quilt heralding a future where sustainable living is both responsible and highly desirable. Modern home comfort to new markets "Matt has been an invaluable advisor to Quilt since our earliest days, and we are thrilled to officially welcome him to our board," said Paul Lambert, CEO of Quilt. "His deep industry expertise, proven business acumen, and collaborative spirit will be instrumental as we scale and bring our vision for modern home comfort to new markets nationwide." Incredible technology and people-centric approach “Quilt has developed technology that will change what is possible with smart climate control inside our homes. It gives people the ability to manage heating and cooling in a way thatʼs intuitive, effortless and cost-effective. Not only is this a better experience in your home, itʼs better for the planet too." "I love this combination of incredible technology and a people-centric approach. I am excited to join the board and continue to support Quiltʼs vision for the future,ˮ Matt Rogers, CEO, Co-Founder of Mill and Founder of Incite.

The Plumbing and Heating Federation (SNIPEF) has raised concerns that the Scottish Government’s announcement on a revised Heat in Buildings Bill failed to address the core challenge of how decarbonization will be delivered, with no mention of workforce skills, installer training or targeted support for small and medium-sized businesses (SME’s). This support is crucial, as 80% of heat pump installations are expected to be completed by SME’s. How Scotland will develop the skilled workforce While welcoming the move to more realistic long-term targets and a renewed focus on fuel poverty, SNIPEF said the announcement lacked critical detail on how Scotland will develop the skilled workforce and business capacity required to install low-carbon heating at scale. Fiona Hodgson, Chief Executive of SNIPEF, said: “We support the Government’s intention to move away from immediate restrictions on homeowners and instead focus on national targets. That change of tone is constructive and gives the plumbing and heating profession a clearer signal on the direction of travel." Rising apprenticeship costs SNIPEF represents over 700 member firms using more than 3,500 plumbing and heating experts Hodgson added: “But today’s announcement is silent on how the work will actually get done. There is no reference to skills, vocational training or business support; yet these are the foundations on which success depends. Without them, we risk setting targets that are simply undeliverable.” SNIPEF, which represents over 700 member firms employing more than 3,500 plumbing and heating professionals, also highlighted the financial strain facing smaller businesses, particularly in relation to rising apprenticeship costs following the significant increase in minimum apprentice wage rates. Policy measures The Federation is calling on the Scottish Government to ensure that the forthcoming Bill and accompanying policy measures include: Dedicated and accessible funding for SMEs to support upskilling and investment in low-carbon technologies Increased investment in apprenticeships and vocational education to grow a future-ready workforce Clear, stable policy direction that enables businesses to plan and invest with confidence. Skills, training, and SME capacity “Around 80% of our members still work in the traditional heating market,” Hodgson added. “They are willing to play a key role in Scotland’s transition, but they can’t do that without practical support. Skills, training and SME capacity must be at the heart of the next stage." “Apprenticeship funding has remained stagnant for over eight years, placing additional financial strain on small businesses already managing rising employer National Insurance contributions, increased minimum wage rates and growing operational costs. These pressures are real, and without targeted intervention, they risk choking off the very workforce we need to deliver change.”

The power grid is undergoing a transformation to keep pace with the rising energy demands of our modern era. This shift is driven by major trends such as the electrification of transportation and HVAC systems, as well as the rapid expansion of AI and renewable energy. Smart Grid The goal is to evolve the traditional electric infrastructure into a more advanced To enhance capacity, resilience, and adaptability, the goal is to evolve the traditional electric infrastructure into a more advanced "Smart Grid." This modernization takes inspiration from Industry 4.0, which leverages tools such as sensors, IoT, and data analytics, to revolutionize operational efficiency across all sectors of the economy. The cornerstone of this digital ecosystem is the intelligence it brings to grid operations, offering valuable insights and actionable data. It enables real-time asset health monitoring and supports proactive, condition-based maintenance. By identifying potential issues early, operators can implement predictive strategies—such as refilling gas or replacing O-rings—before failures occur. This condition-driven approach addresses problems based on the actual state of equipment, reducing the risk of unexpected breakdowns, lowering the need for expensive emergency repairs, and extending the lifespan of critical, high-value assets. The Role of Advanced Gas Density Sensors A key enabler of this transformation is the adoption of advanced gas density sensors in gas-insulated switchgear (GIS). Since the 1980s, GIS has become widely popular due to its compact design, excellent reliability, and ability to handle higher voltage levels efficiently. High-voltage switchgear has evolved significantly—from the bulky air-insulated switchgear (AIS), which occupied the size of a football field, to GIS systems that require just 10% of that space. This innovation is possible thanks to pressurized chambers filled with highly compressed insulating gas, which house the high-voltage components. This gas effectively prevents or extinguishes arc faults and short circuits, enabling more reliable and space-saving power systems. Critical Gas Density Sulfur hexafluoride is the most effective gas for insulation and arc extinguishing at high voltages Sulfur hexafluoride is the most effective gas for insulation and arc extinguishing at high and extra-high voltages. However, SF6 has a greenhouse gas effect 23,500 times greater than CO2, making even small leaks unacceptable. For this reason, strict regulations worldwide demand rigorous monitoring to prevent SF6 from escaping. Effectively monitoring insulating gas density is more critical than ever for ensuring the reliability and safety of gas-insulated high-voltage systems. Maintaining proper gas density within pressure compartments is essential to prevent functionality issues, safety risks, and environmental violations caused by leaks. This is also critical as the industry explores less environmentally harmful alternatives to SF6, which still require precise monitoring to ensure sufficient insulating gas levels are maintained. Predictive Maintenance Utilities now face dual challenges: operating plants without interruptions and reducing plant sizes. This has led to a shift toward continuous electronic density monitoring and predictive maintenance over traditional warning and shutdown systems. As smaller compartments with reduced insulation volumes become the norm, tighter gas monitoring is essential. Traditional Gas Density Monitoring Pressure gauges, using Bourdon tubes and bimetallic temperature compensation, were once standard for monitoring systems. While cost-effective, they are less precise due to design limitations. Gas density is typically inferred from pressure using manometers or sensors, but significant temperature variations in closed systems lead to inaccuracies without proper compensation. In a closed, gas-insulated system, the number of gas molecules (density) remains constant, but pressure and temperature vary based on isochores. Outdoor installations face temperature extremes from -40°C to +60°C, requiring precise temperature compensation to avoid false readings. Without this, sunlight or frost can cause density displays to fluctuate, even when the actual gas density remains unchanged. Extreme Condition Challenges Outdoor installations are an increasing share of gas-insulated switchgear (GIS) setups due to the rapid growth of renewable energy projects and the rising need to support bulk power transfers across long distances. Bimetallic temperature compensation must be tailored to the insulating gas, but large temperature fluctuations can lead to significant measurement inaccuracies. At extreme temperatures, these inaccuracies increase further, resulting in false alarms. Reliable gas density monitors must withstand harsh conditions, function across varying altitudes and pressures, and ensure continuous, accurate measurements. Breakthrough in Accuracy Traditional temperature-compensated pressure gauges fell short when it came to reliable gas density monitoring, often lacking the precision needed and leading to false alarms. To address this, Trafag AG, in collaboration with switchgear manufacturers, revolutionized the field in 1987 with the introduction of an innovative reference chamber system. This advancement significantly outperformed conventional manometer-based designs, offering greater accuracy and reducing the occurrence of false alerts. Unlike conventional density gauges, Trafag’s system uses a reference gas housed in an isolated reference chamber. This reference gas mirrors the properties of the insulation gas within switchgear components. Both gases are thermally coupled, maintaining identical temperatures, which eliminates pressure variations caused by temperature changes. By design, the monitors are fully temperature-compensated, delivering a level of accuracy that surpasses standard pressure gauges. Why Accuracy Matters When insulation gas pressure drops, the reference chamber system activates precise mechanical switching points via microswitches. At the first alarm level, operators are prompted to refill the insulation gas. Only a rapid and significant pressure loss triggers an automatic system shutdown, thanks to the system’s reliable secondary switching points. This high level of accuracy has significant benefits. Density monitors designed with narrow alarm thresholds enable more compact and efficient plant designs. With greater measurement precision, insulation volumes can be reduced, allowing for smaller, optimized systems. This minimizes the site area required for switchgear installations. In contrast, less accurate density monitoring necessitates larger volumes and broader tolerances, resulting in bulkier, less efficient designs. Continuous Monitoring Gas monitors have improved measurement accuracy by reducing temperature distortions Gas monitors with reference chamber designs have significantly improved measurement accuracy by reducing temperature-related distortions. But these systems have inherent limitations. They only provide precise readings at specific moments, triggered when pressure crosses a microswitch threshold, providing only intermittent data points. This limitation leaves gaps in system visibility, requiring engineers to rely on data interpolation or trend extrapolation to evaluate and predict system performance. As the power distribution industry increasingly relies on real-time, high-resolution data for advanced analytics and preventative maintenance, the need for continuous monitoring has become crucial. To address this challenge, a significant breakthrough emerged in the mid-1990s with the introduction of Trafag's electronic density sensor. Accurate Gas Measurement This innovation utilized quartz tuning fork technology—a method commonly used in timekeeping devices—to enable continuous, drift-free gas density measurement. By measuring changes in resonant frequency as the tuning fork oscillates within the gas, this technology provides continuous, real-time monitoring. The density sensors are mounted to the pressure compartment via a customizable process connection, ensuring equilibrium between the insulating gas in the compartment and the sensor's measurement chamber. The system uses two quartz oscillators: one in a vacuum and the other surrounded by the insulating gas. By comparing their resonant frequencies, the sensor determines the gas density with exceptional accuracy. Density Detection Gases of different densities alter the predetermined resonant frequency of the quartz tuning fork surrounded by the process gas. This shift in frequency is proportional to the gas density, with a response time of less than 10 milliseconds—ideal for detecting rapid density changes. Additionally, a built-in temperature sensor refines the measurement for even greater reliability. Condition-Based Preventive Maintenance Digital gas density sensors with continuous monitoring capabilities enable the shift from traditional time-based preventive maintenance to a more efficient, condition-driven approach. Time-Based Maintenance: Maintenance has traditionally been scheduled based on factors such as material aging and the environmental conditions in which equipment operates. This approach aims to prevent failures by servicing or replacing parts at set intervals. However, it often leads to unnecessary replacements and increased costs, as components may not always require maintenance when scheduled. Efficient Upkeep Condition-Based Maintenance: In contrast, condition-based maintenance is based on the actual, real-time state of the equipment. By monitoring the condition of components, this strategy identifies which parts require attention, allowing operators to perform maintenance only when wear or degradation is detected. This targeted approach not only reduces unnecessary downtime but also extends the lifespan of components by addressing issues before they escalate into major failures. It represents a more efficient and cost-effective way to manage equipment. Predictive Insights With the implementation of continuous monitoring, operators gain a comprehensive and accurate understanding of the gas's current state and its evolution over time. The sensors provide high resolution data that can be analyzed to spot trends, enabling predictive maintenance and more informed decision-making. Preparing for the Future The shift toward a smarter, more intelligent grid, coupled with condition-based maintenance, represents a gradual evolution rather than a sudden revolution. This transformation takes time, and systems are adapting at different speeds. However, even those in the early stages of this transition can recognize the direction the industry is heading. Given that gas-insulated switchgear typically has a lifespan of 30-40 years or more, it is prudent to future-proof infrastructure. As a result, some are turning to hybrid systems. The hybrid gas density monitor combines the advantages of a mechanical monitor with a reference gas chamber and the advanced functionalities of an electronic gas density sensor, all integrated into a compact, multi-functional device. With continuous measurement output, it is ideally suited for gas management and trend analysis systems. It also includes a local display and durable switchpoint alarm contacts for enhanced reliability. Smart Grid Integration Even if the current digital ecosystem is not fully equipped to utilize the continuous monitoring and real-time data provided by the electronic gas sensor, this technology is seamlessly embedded within the equipment. This ensures its availability for future use as grids evolve and become more compatible with smart technologies.

Expert Commentary

The HVAC/R industry is in the process of a major shift as A2L refrigerants become the standard in residential and commercial system HVAC. This change is being propelled by stricter environmental policy and advancements in refrigeration technology. However, the transition is not without its hurdles, posing new considerations for system owners, technicians, and equipment manufacturers. Favor of GWP alternatives The Environmental Protection Agency (EPA) has established clear guidelines to phase out hydrofluorocarbons (HFCs) in favor of lower global warming potential (GWP) alternatives. The 700 GWP limit imposed by the EPA, forced manufacturers away from non-flammable A1 to mildly flammable A2L refrigerants for comfort cooling chillers and air-to-air unitary equipment. R-410A split systems Under current regulations, R-410A split systems can still be installed until January 1, 2026 Under current regulations, R-410A split systems can still be installed until January 1, 2026, but manufacturers had to halt production of R-410A-based equipment by January 1, 2025. As for packaged systems, which are fully assembled and sealed at the factory, sales will remain permitted until January 1, 2028, but only for equipment manufactured before 2025. Adaptation of A2L refrigerants These regulatory milestones mark a significant step toward a new era in HVAC/R technology, emphasizing sustainability and compliance with modern environmental standards. While the transition is underway in our market as we speak, there are some key factors that play into the adaptation of A2L refrigerants. How we implement, gain familiarity, and roll out these systems provides challenges. System Design Modifications ASHRAE Standard 15 first added these requirements in its published version of 2019 ANSI/ASHRAE Standard 15 is widely recognized as the preeminent guide for the safe use of refrigeration equipment, as evidenced by its inclusion in building codes at the state and local level. ASHRAE Standard 15 first added these requirements in its published version of 2019. For high-probability systems, in which the basic design or the location of components is such that a leakage of refrigerant from a failed connection, seal, or component could enter the occupied space, these requirements underwent major revisions for the 2022 version, with intent to better harmonize with the requirements in UL 60335-2-40. Modifications in HVAC system design The transition to A2L refrigerants necessitates modifications in HVAC system design to ensure compatibility and safety. One significant consideration is component compatibility; all system components, including compressors, heat exchangers, and expansion devices, must be rated for A2L refrigerants to ensure optimal performance and safety. Failure to use appropriate components could lead to operational inefficiencies or increased safety risks. Component Testing/Approval Requirements UL 60335-2-34 is a safety standard that applies to motor-compressors used in refrigeration systems UL 60335-2-34 is a safety standard that applies to motor-compressors used in refrigeration and air-conditioning systems. The UL 60335-2-34 6th edition was established in 2017 as the safety standard for compressors, introducing several key updates. One major change is the requirement for a new Maximum Rated Current marking, ensuring clear identification of electrical ratings. Additionally, the standard introduces various new testing methods for motors and their protective mechanisms to enhance safety and reliability. Testing methods outlined in UL 207 UL207 covers “Refrigerant-Containing Components and Accessories, Nonelectrical” which are components Danfoss refers to as “line components”, such as filter driers, expansion valves and pressure regulating valves. The testing methods outlined in UL 207 include burst pressure tests, fatigue tests, and hydrostatic tests to verify nonelectrical refrigerant-containing components and accessories. UL 207, which remains a referenced standard under UL 60335-2-40, has been reapproved for use with R-454B. Dealing with A2L refrigerants Compliance can be achieved through burst testing at five times the maximum pressure rating Unlike A1 refrigerants, where leaks at gaskets or mechanical seals were not a concern at twice the maximum pressure, such leaks now pose a significant issue when dealing with A2L refrigerants. Compliance can be achieved through burst testing at five times the maximum pressure rating or by conducting a fatigue test at three times the maximum pressure rating without the product bursting or leaking from any mechanical connection. Implementation: Choosing a Solution Understanding what makes sense for your sector of the market for this transition is paramount in how OEMs will implement (and many already have) A2Ls into the next generation of equipment. Let’s zoom in and look at the HVAC segment related to commercial A/C units. The two main A2L refrigerants that were approved via SNAP rule 26, being used to replace R-410A in the 2025 transition requirement, are R-32 and R-454B. These two offer different approaches to the design requirements needed to be implemented. R-454B Danfoss has a selection tool called Cool Selector® 2 that is free to download online While no refrigerant is a direct replacement for R-410A, R-454B which has a GWP of 466, is considered a relatively close “drop in” solution. As such, most major components of the system, such as compressors and heat exchangers, can usually stay the same size. This is the lowest GWP solution available in the “high-pressure” range. With that being said, R-454B operates at lower pressures than R-410A, it also operates at lower mass flows than R-410A. This can leave your current liquid line, liquid line solenoid, expansion device slightly oversized. It is considered good practice to verify the sizing of these existing components when introducing R454B. Danfoss has a selection tool called Cool Selector® 2 that is free to download online. This can help you in verifying Danfoss components. R-32 If the transition to A2L refrigerants is going to coincide with a major redesign of that unit, then R-32 (GWP 677) may be an option for your transition. R-32 will work at overall higher operating pressures and provide a significant increase in capacity vs R-410A. But with this comes the reality that most components in the system, possibly including piping sizes, will need to be changed to better suit the use of R32. R32 as a refrigerant, will also generate higher discharge temperatures than systems running with R-410A, creating a problem that manufacturers will need to account for in low ambient heat pumps and high condensing temperature environments. Leak Detection and Mitigation Refrigerant leak detectors must be installed in every unit with individual circuits charged with 4lbs As A2Ls pose a higher flammability risk, effective leak detection and mitigation strategies are essential for maintaining safety in environments where A2L refrigerants are used. Refrigerant leak detectors must be installed in every unit with individual circuits charged with 4lbs of A2L refrigerant or more. More details on charge limits for systems and what mitigations requirements are needed can be found in UL60335-2-40 Annex GG. These detection systems enable quick identification and response to refrigerant leaks, reducing the potential for accidents or equipment damage. Danfoss leak detectors use thermal conductivity technology, were among the first to be UL-approved a year ago and come in a variety of configurations for HVAC/R equipment manufacturers. Proper mitigation strategies Proper mitigation strategies are crucial for preventing refrigerant accumulation in case of leaks. They must be tied into the unit control scheme. Disengaging any heating elements eliminates the possibility of ignition sources. Engaging evaporator fans increases circulation, ensuring that any leaked refrigerant is quickly dispersed, minimizing the likelihood of hazardous concentrations forming. In addition, per UL60335-2-40, service and maintenance procedures must incorporate regular leak inspections as a standard practice. Refer to ASHRAE 15 or UL60335-2-40 for further readings and requirements. Service and Familiarity Technicians must gain a version of the parts of A2L refrigerants and are required to pass an A2L test While manufacturers focus on design changes to accommodate the A2L transition, industry members who will install and service units also must adjust to the changing landscape of refrigerant. Technicians must gain an understanding of the characteristics of A2L refrigerants and are required to pass an A2L certification test under EPA Section 608. Looking Forward This phase of transition is better conceptualized as a mid-term solution. The American Innovation and Manufacturing (AIM) Act was passed in 2020. This directed the EPA to address hydrofluorocarbons (HFCs) and phase down production and consumption of HFCs by 85% by 2036. It is likely in the future, we will see another step in transitions to ultra-low GWP Refrigerants such as R-290 (A3 class), R-1234ze, or R-515B. Before the AIM Act, individual states like California were looking to regulate their own refrigerant marketplaces. As adoption of new EPA regulations might be slowed under the current U.S. administration, it is uncertain if any future deregulation by the federal government could lead to some states restarting their own regulation programs. But as we stand now, lower GWP A2L refrigerants still continue to grow in the marketplace.

Data centers worldwide are under intense pressure. High-powered computing is a global necessity that seemingly gets more demanding by the day. There’s also the need to prioritize sustainability improvements ranging from resource conservation to decarbonization. And data centers must consider their bottom line and remain competitive. Anticipating the challenges data centers will continue to face, scientists and engineers have innovated two-phase (2-PIC) immersion cooling. With the capacity to meet the elevated cooling requirements driven by high-powered computing, this next-generation solution delivers on environmental priorities by significantly lowering data center energy consumption, slashing, if not eliminating, water use, while supporting decarbonization, circularity missions, and more. Emergence of 2-PIC Traditional approaches are fast approaching capacity for meeting current and future cooling needs The emergence of 2-PIC comes at a critical time, because the traditional cooling methods that have kept data centers up and running so far—namely air cooling and water cooling—are doing so at the detriment of the planet. Additionally, these traditional approaches are quickly approaching capacity for meeting current and future cooling needs. Air- and water-cooling methods are used in approximately 95% of the estimated 8,000 data centers that exist today. The criticality of high-powered computing Once seen as a future need, high-powered computing, and faster-than-ever processing are now established as critical to the operation of businesses, governments, organizations, and other entities that support the way communities function, survive, and thrive. Whether it’s health and wellness, financial institutions, economic growth, safety and protection, entertainment, education, or any other service supporting our way of life, successfully providing that service fully depends on the ability of data centers to quickly and reliably obtain, store, and process data. Influence of AI AI has a profound influence and, generates far more power than traditional internet uses Moreover, when we say “data centers,” we’re not just speaking of big players like Microsoft, Google, Meta, and Amazon. Equally dependent on high-performance, high-speed computing are enterprise data center operators, such as our governments and military, financial institutions, healthcare systems, educational institutions, and more. We also must acknowledge the profound influence of artificial intelligence (AI), which generates far more power than traditional internet uses. Its effects are far-reaching, enhancing patient care, supporting risk management and fraud detection in finance, boosting crop yields within agriculture, and more. The environmental costs of data centers According to the latest estimates by the International Energy Agency, data centers worldwide produce 1% of energy-related carbon emissions and in 2022 used approximately 460 TWh of electricity per year—equating to 2% of global electricity demand. McKinsey and Company estimates 40% of this electricity is used for data center cooling. Data centers’ impact on the environment also includes their significant water consumption, averaging 300,000 gallons per day, and a physical footprint that averages 100,000 square feet but in the case of some hyperscale data centers can range between 1.3 to 2 million square feet. In terms of growth, a U.S. market report from Newmark tells us that in the U.S. alone, the U.S. data center footprint will absorb 35 gigawatts by 2030, which is more than twice the data center power consumption of 2022. The emergence of liquid cooling: the elevated interest in 2-PIC From reducing energy and water consumption to shrinking physical footprints, 2-PIC offers the planet a better data center solution. In less than two years, traditional cooling systems won’t be able to support the exponential growth in the world’s data processing and storage applications. Based on publicly available product roadmaps from major chip manufacturers, by 2026, air-cooled systems will no longer be able to meet the cooling needs of most next-generation, high-performance computing chips. Capable of removing heat more effectively than air cooling, liquid cooling uses a liquid such as water or a dielectric fluid to cool the heat-generating components of servers. The liquid can cool these components directly, or it can be done indirectly through a heat exchanger. With two-phase immersion cooling the entire server rack is submerged in a tank filled with a dielectric fluid. Single-phase and two-phase liquid cooling Single-phase liquid cooling uses a pump to circulate the liquid through a closed-loop system Single-phase liquid cooling uses a pump to circulate the liquid through a closed-loop system. Two-phase liquid cooling uses a phase-change material, such as a refrigerant, which evaporates and condenses as it absorbs and releases heat. With 2-PIC, which is a form of two-phase liquid cooling, the entire server rack is submerged in a tank filled with dielectric fluid. The fluid boils as it’s heated by the components of the servers, creating bubbles that rise to the surface and condense in a heat exchanger. Gravity then returns the condensed fluid to the tank, creating a natural circulation loop that does not require pumps or fans. Advantages of 2-PIC 2-PIC is commanding attention as the solution for meeting the cooling demands of the high-powered computing components of today and tomorrow. Moreover, the technology of 2-PIC systems, combined with the right dielectric fluid, delivers advantages to “take the heat off” data centers. Here’s a breakdown of additional 2-PIC benefits: Up to 90% reduction in energy consumption: Based on modeling completed by the industry, 2-PIC is expected to reduce up to 90% of data center cooling energy consumption and 40% of overall data center energy consumption*. (*Compared to traditional air-cooling technologies) Enhanced computing performance and data center reliability: 2-PIC allows servers to operate at higher temperatures and power densities, while reducing the risk of overheating. Significant reduction in water consumption: Depending on the data center location and cooling design methodology, water consumption could even be eliminated completely. 60% reduction in the physical footprint: 2-PIC reduces the space required for cooling equipment, freeing up more floor area for servers and increasing the rack density of the data center. Lower GWP and circularity: Chemours Opteon™ 2P50 is a developmental dielectric heat-transfer fluid, currently pre-commercial, pending regulatory approval. It offers an extremely low global warming potential (GWP) of 10 and was specifically created to optimize the performance of the electronic components in a 2-PIC system. This 2-PIC fluid also enables the reprocessing/reuse of existing fluid to maximize circularity. The bottom line: In addition to other compelling data, a recent study commissioned by Chemours and LiquidStack through Syska Hennessy, revealed that, compared with other state-of-the-art liquid cooling methods, 2-PIC can deliver up to a 40% lower total cost of ownership (TCO) and significantly reduce operational expenditures (OPEX), with savings ranging from 54% to 88.6%. Benefits of new data center cooling technologies compared to single-phase direct-to-chip, and single-phase immersion methods. 2-PIC, the future-ready solution As the world’s reliance on AI and other high-powered computing capabilities escalates, data center cooling solutions must grow with demand while significantly reducing their impact on the environment. In global energy savings alone, 2-PIC could generate an estimated savings of 340 TWh by 2055—the equivalent of powering more than 517 million laptops 24/7. And even with increasing IT loads, 2-PIC maintains its performance, ensuring long-term cost-effectiveness and adaptability to meet future demands. With society at a crossroads between the criticality of high-powered computing and a planet in crisis, the industry is turning its attention to 2-PIC as the solution for today and tomorrow.

Until a couple of years ago, most of the talk about heat pumps occurred around this time of year, when more than half the planet prepares for an autumn cooldown. These discussions were typically limited to regions that only experienced moderate winters. But as anyone who has recently perused an HVACR trade magazine or website—or participated in an industry webinar, event, or social media conversation—can tell you, the topic of heat pumps is virtually unavoidable. Not only do heat pump discussions now occur year-round, but they’ve also ascended to consistent headline status and transcended the traditional boundaries of moderate climates. The decarbonization megatrend One might say heat pumps have taken their place on the global stage. If you’re asking why this has happened, the answer requires just three words: the decarbonization megatrend. However, for industry professionals looking to grow their businesses, it’s helpful to gain a deeper understanding of heat pumps—how they work, ways they are currently meeting HVACR needs, and where the technology is headed for next-generation applications. Through this understanding, members of the industry can better forecast customer needs as well as identify opportunities for expanding in both current markets and, potentially, new ones. How heat pumps work—don’t let the name fool you The heat released as the refrigerant condenses is then transferred to interior spaces What heat pumps do and, more specifically, how they do it provides the key as to why they are now being considered a “hero” of decarbonization. The term can be misleading, because “heat pumps” do not generate heat. Because of this, heat pumps are being more widely embraced as the lower-carbon-emission alternative to combustion-based heating technology that uses, for example, fossil fuels. Instead of creating heat, heat pumps extract heat energy from where it’s not needed and move it to where it is needed. When a heat pump is in heating mode, its refrigerant evaporates as it absorbs heat from the outside. The heat released as the refrigerant condenses is then transferred to interior spaces. In warmer weather, a heat pump kicks into cooling mode and the process is reversed, as heat is extracted inside and released outside. This non-combustion process of moving heat from one place to another provides several potential benefits to society: Heat pumps support the megatrend toward decarbonization. They replace fossil-fuel heating with high-efficiency technology. They can be paired with lower-global-warming-potential (GWP) A2L refrigerants—such as R-454B and R-32—to further increase environmental benefits, while offering similar performance to the legacy R-410A. They offer the ability to tap into alternative energy sources, such as industrial waste heat as well as heat sourced from the air (ambient), ground (geothermal), or lakes/ponds (water). Meeting today’s needs—these aren’t your grandfather’s heat pumps Heat pump technology has been commercially available and in use since the 1950s. Early versions of heat pumps were essentially reversible air conditioning units, and most used traditional refrigerants—like R-22 and, more recently, R-410A. These units performed well and operated safely using lower-toxicity, nonflammable (A1) refrigerants. However, they were known to sometimes struggle at lower ambient temperatures. As often happens in the world of science and technology, challenges drive the search for solutions. Today, we’re seeing innovations that result in efficient, effective cold-climate heat pumps that optimize various components, such as compressors, heat exchangers, expansion valves, and their controls. Thanks to these innovations and others, the U.S. and other countries are experiencing broader heat pump adoption and, in turn, supporting progress toward decarbonization. Heat pump technology has been commercially available. Increasing heat pump accessibility and viability in more places and spaces is also critical to the HVACR industry’s commitments to the environment—and its need to heed regulations advancing the transition to systems reducing climate impact. Emerging systems use mildly flammable (A2L) refrigerants. They are similar in design to legacy systems and include modifications to mitigate risks associated with the change to A2Ls. Where things are headed—heat pump technology is just getting started Even with the significant advances we’ve seen in colder-climate heat pumps, there is still untapped potential in terms of what the technology can achieve. We can expect to see continued innovation as end-user needs and environmental priorities continue to evolve. Some foreseeable growth areas for heat pumps include: Traditional applications—that is, moderate climates Expansion into nontraditional climates—heating in very cold climates and cooling in hotter regions Domestic water heating, replacing fossil-fuel systems Leveraging a variety of heat sources—geothermal, air-sourced, and water-sourced Harnessing waste heat generated by energy-intensive industrial processes Use of lower-GWP A2L refrigerants System optimization will also drive greater use of lower-GWP A2L refrigerants, such as R-454B Supporting these growth areas will be innovations that optimize high-performance, high-efficiency delivery of extracted heat, using a combination of traditional and new split-ducted, ductless/mini-split, and mono-block technologies. System optimization will also drive greater use of lower-GWP A2L refrigerants, such as R-454B, while limiting the use of highly flammable refrigerants such as R-290. Refrigerant selection will also play an increasingly important role and may offer additional opportunities for application-specific technology. As heat pump applications expand, we can expect to see greater focus on selecting the optimum refrigerant to use as the working fluid. Criteria will weigh system design, operating conditions, and other priorities against key refrigerant properties: Physical—boiling point, vapor pressure, density, and material compatibility Thermodynamic—cooling/heat capacity, energy efficiency, pressure-enthalpy (PH) curves Environmental—ozone depletion potential (ODP) and global warming potential (GWP) Safety and health—flammability and toxicity Conclusion: There’s strong and ample reason to “stay pumped” Over the past several years, members of the HVACR industry have enthusiastically embraced new heat pump solutions. Evolving heat pump technology and expanding applications will continue as the industry progresses along the path of more energy-efficient, lower-GWP, and more sustainable new-generation and next-generation heating and cooling. This, coupled engineering and science that leverages untapped heat pump potential, will mean more opportunities for HVACR contractors to deliver new options to the markets they serve. With a strong understanding of their customers’ individual heating and cooling needs, climate challenges, and sustainability goals, contractors can confidently select the best heat-pump refrigerant solution.

Editor's Note