The Chemours Company - Experts & Thought Leaders

Latest The Chemours Company news & announcements

When a company is one of the largest beverage distributors in the U.S., it’s crucial to stay ahead of the curve on everything that drives customer satisfaction, corporate responsibility, and a strong bottom line. Hensley Beverage Company did exactly that when it collaborated with Chemours and American Refrigeration Supplies, Inc. (ARS) to implement a system utilizing a new-generation A2L refrigerant, Chemours Opteon™ XL20 (R-454C). Completed in 2023, the installation paves the way for companies throughout the commercial refrigeration industry to embrace refrigerant technologies that are both cost-effective and environmentally sustainable. Situation Hensley Beverage, a Phoenix-based beverage wholesaler, supports a customer base of more than 9,000 accounts and more than 2,500 individual products, operating out of six locations across Arizona, USA. Hensley remains committed to maintaining exceptional product integrity, upholding its business legacy The company recently completed an acquisition that expanded its distribution footprint into New Mexico, making it one of the nation's largest family-owned and operated beverage distributors. As it grows, Hensley remains committed to maintaining exceptional product integrity, upholding its multi-generational family business legacy, and supporting various environmental objectives. Upgrading refrigeration systems These factors, coupled with the current regulatory landscape (notably, the phasedown of legacy hydrofluorocarbon (HFC) refrigerants), have put Hensley’s focus on ways to upgrade its refrigeration systems. For the past several years, Chemours, ARS, and Hensley have worked together to retrofit the distributor’s existing R-22 and R-404A systems to Opteon™ XP40 (R-449A), a hydrofluoroolefin (HFO) blend offering zero ozone depletion potential (ODP) and a significantly lower global warming potential (GWP) than legacy products. Phasedown of HFC refrigerants Hensley Beverage is proud to partner with Chemours, TBSI, and ARS to help develop innovative solutions" However, with the ongoing phasedown of HFC refrigerants under the U.S. EPA’s American Innovation and Manufacturing Act (AIM), the teams began weighing the benefits of an even bolder upgrade. “Hensley Beverage is proud to partner with Chemours, TBSI, and ARS to help develop innovative solutions and responsible business practices that drive sustainability in our community," said Alex Dunn, SVP of Operations, Hensley Beverage. Partnership and collaboration Alex Dunn adds, "These groundbreaking results are a culmination of partnership and collaboration. It is refreshing to work with three organizations that are this passionate about developing pioneering products that will help shape a better future for the communities we serve.” Solution A mildly flammable refrigerant with an ASHRAE A2L safety classification, Opteon™ XL20 is designed for use in new equipment Even as Chemours, ARS, and Hensley continued to employ retrofit solutions in some areas strategically, they explored options that would put the company in a stronger position for the long term. Chemours recommended bringing Opteon™ XL20 (R-454C) into Hensley’s refrigeration plan. A mildly flammable refrigerant with an ASHRAE A2L safety classification, Opteon™ XL20 is designed for use in new equipment, so Hensley identified an old R-22 system near the end of its life that was ideal for replacement by a new system using Opteon™. Opteon™ XL20 Opteon™ XL20 has been used for several years in Europe and is expected to become the new norm in the U.S. by 2026, based on the current direction provided by the EPA. Leveraging its experience in Europe, the Chemours team of technical service and business development resources is prepared to support end users as they consider trial installations using A2L refrigerants. Opteon™ XL20 - The future of sustainable low- and medium-temperature refrigeration: GWP of 148 (a 96% reduction versus R-404A). Zero ODP. Enables much higher charge sizes than highly flammable A3 refrigerants. Is a close performance match to R-22 and R-404A. Offers the optimum balance of performance and environmental sustainability. Provides an easy, cost-effective alternative to legacy refrigerants and new equipment applications. Utilizes well-known technology for ease of service and maintenance. performance, efficiency, and sustainability “Hensley was an early adopter of Opteon™ XP40, retrofitting equipment to experience better environmental outcomes, as well as high performance in low- and medium-temperature applications. Experiencing these benefits of HFOs whet their appetite to ask, ‘What next?’," said Joe Martinko, President of Thermal and Specialized Solutions, Chemours. Joe Martinko adds, "With a strong dedication to supporting their communities and the environment, while operating an efficient and thriving business, Hensley is a company that pushes the envelope. Chemours was ready with our next-generationOpteon™ XL20, which will ensure they achieve maximum performance, operating efficiency, and sustainability." servicing and Installation Heatcraft and Copeland had the knowledge and experience of emerging A2L requirements The installation brought together additional resources from the HVACR industry, including Copeland and Heatcraft Refrigeration Products, two ARS manufacturing partners as well as Technical Building Services, Inc. (TBSI), the local HVAC service provider. As global HVACR technology pioneers helping customers achieve their sustainability, decarbonization, and regulatory compliance goals, Heatcraft and Copeland had the knowledge and experience of emerging A2L requirements and the capabilities to support the project. TBSI was selected as the contractor for installation and servicing. Time- and cost-efficient With the team assembled, Chemours took the head on the project, ensuring that the contractor, Hensley’s service personnel, and others involved were certified through the ESCO Institute’s A2L refrigerant training program, and answering any questions from the local authorities. After safely recovering the R-22 for use in other Hensley systems, the team from TBSI started removing the existing Keg 6 equipment, hanging new evaporator coils, and running new refrigerant lines. Installation, evacuation, and charging procedures were very similar to the current refrigerants in use by industry, making for a time- and cost-efficient process. Climate technology Copeland has always been focused on not just setting the standard in climate solutions" “Copeland has always been focused on not just setting the standard in climate solutions with pioneering brands in compression, controls, software, and monitoring, but pioneering the evolution in this space. Our role in the system design and installation for Hensley was right in our wheelhouse," said Brian Schroeder, Engineering Manager, Refrigerants, Copeland. Brian Schroeder adds, "What we accomplished together demonstrates that by bringing together energy-efficient products,regulation-ready solutions, and expertise, we can revolutionize the next generation of climate technology for the better.” R-454C refrigerant “Our tools and gauges were already enabled for the R-454C refrigerant. The startup and charging of both systems went pretty smoothly," said Sergio Pelayo, Vice President of TBSI. Sergio Pelayo adds, "TBSI is proud to have participated in the project at Hensley and, by doing so, added to the variety of equipment we’ve worked on since founding our business in 1990. This was a great opportunity to grow our experience with A2Ls.” Copeland monitoring data Copeland applied monitoring units to the systems that capture nearly two dozen data points every second To make sure the system performed as expected, Copeland applied monitoring units to the systems that capture nearly two dozen data points every second. The data has shown that the systems are running as designed. “We are thrilled with the results of the R-454C project with Hensley Beverage," said Bob Landi, Vice President and General Manager of Heatcraft Refrigeration Products. Bob Landi adds, "As we continue our journey toward new regulation compliance, this successful collaboration has been instrumental in leveraging Heatcraft’s new product design efforts, with A2L refrigerants being an important part of the mix. We are poised to head the industry and provide more customers like Hensley with cutting-edge solutions that drive their success.” Summary Influenced by upcoming regulatory changes and stronger organizational ESG commitments, the commercial refrigeration industry’s transition to lower GWP refrigerants is inevitable. Opteon™ refrigerants provide organizations with lower GWP options that can help extend the useful life of their systems, as well as new equipment options that enable decades of reliable operation. Moreover, these systems answer the consumer preference for businesses that utilize responsibly manufactured products and support a greener environment. Hensley’s approach Hensley’s approach demonstrates an ideal way for companies to meet the needs of refrigerating their products while following the guidelines of the HFC phasedown. It’s important to assess where equipment is in its lifecycle and determine if it makes the most sense in terms of budget, performance needs, and corporate vision to 1) retrofit existing equipment for more efficient and sustainable operation or 2) replace it with A2L refrigerant technologies and products.

The Chemours Company, a global chemistry company with pioneering market positions in Titanium Technologies, Thermal & Specialized Solutions, and Advanced Performance Materials announced the creation of an international F-gas Lifecycle Program across the Americas, Asia, and Europe. The program aims to advance the safe, global recovery, reclaim, and reuse of fluorinated gases (F-gases) across its low global warming potential (GWP) Opteon™ products, Freon™ refrigerants, and FM-200™ portfolios. global oversight This program, which began as region and country-specific initiatives, will include global oversight to drive additional adoption, partnerships, and reclamation. As part of the program, Chemours will complete a global review to identify opportunities for expansion and increased collaboration. global circular economy Chemours’ commitment to supporting a global circular economy and the UN’s Sustainable Development Goals This announcement reinforces Chemours’ commitment to supporting a global circular economy and the United Nations’ Sustainable Development Goals, as outlined in its recent Chemours Sustainability Report. It also advances the net zero objectives of Chemours, broader industry, and global legislative bodies through overall emission reduction. F-gas Lifecycle Program Chemours’ international F-gas Lifecycle Program includes agreements across the: 1) Americas Canada The United States 2) Asia Pacific Japan 3) Europe All 27 countries in the European Union United Kingdom sustainable and circular future “At Chemours, we are dedicated to harnessing the power of our chemistry to create a more sustainable and circular future,” said Joe Martinko President of Thermal & Specialized Solutions (TSS) at Chemours. “We have committed to, and are advancing, significant emission reduction within our gates. Now, we’re expanding our focus to emission reduction throughout the product lifecycle." F-gases This international F-gas Lifecycle Program will help advance circularity and sustainability around the world" "F-gases, unlike so-called “natural” alternatives can be recovered, reclaimed, and reused across multiple applications, maximizing resource efficiency, minimizing waste, and lowering emissions." "This international F-gas Lifecycle Program will help advance circularity and sustainability around the world, ultimately supporting global climate targets and minimizing impact on our shared planet.” role in decarbonization The company continues to invest in and expand reclaim channels, including in the US and the recent extension of its EU and UK programs to reclaim low GWP refrigerants. In addition to offering the potential for circularity, Chemours’ portfolio of F-gas technologies also plays an important role in the decarbonization of multiple industries and delivers significant socioeconomic value through innovation, reliability, safety, and efficiency.

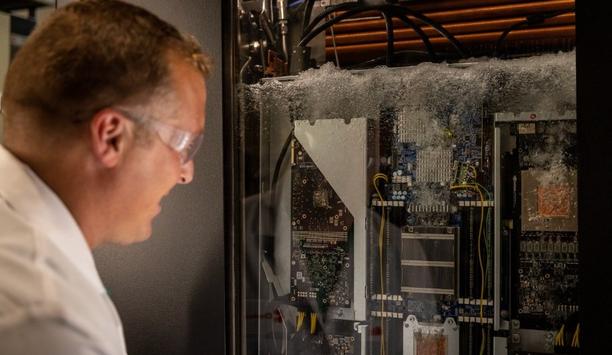

The Chemours Company (“Chemours”), a chemistry company with pioneering market positions in Titanium Technologies, Thermal and Specialized Solutions, and Advanced Performance Materials, recently announced important achievements in the development and manufacture of Opteon™ 2P50, a new heat-transfer fluid for two-phase immersion cooling (2-PIC). The proprietary fluid is currently in the final testing stages for manufacturing capability, with initial commercialization targeted for 2025, pending appropriate regulatory approvals. Chemours’ Opteon™ 2P50 Opteon™ 2P50 offers zero ozone depletion potential (ODP) and substantially lower GWP Chemours’ Opteon™ 2P50 is a proprietary hydrofluoroolefin (HFO) dielectric fluid designed to meet the growing demand for high-performing products that reduce environmental impact, while enabling circularity. Opteon™ 2P50 offers zero ozone depletion potential (ODP) and substantially lower global warming potential (GWP), when compared to incumbent fluid. Chemours’ introduction of Opteon™ 2P50 represents a critical step in positioning the company to meet a growing challenge brought on by a new era of data transmission driving a dramatic increase in demands for faster computing, AI capabilities, and other cutting-edge applications — all of which are based in technologies requiring elevated cooling capacities. Chemours’ new 2-PIC fluid enables high-performance computing and energy-efficient cooling across a broad range of thermal management applications. Two-phase immersion cooling “Two-phase immersion cooling represents a tremendous unmet market need and Chemours is excited to be entering this space and investing in the present and future needs in such a significant way,” said Natalia Duchini, Senior Director, Global Technology at Chemours. Natalia Duchini adds, “We’ve innovated a next-generation fluid that meets or exceeds our customers’ most critical criteria for performance and efficiency. Moreover, by putting the power of our chemistry to work, it also ensures sustainability in an evolving environmental landscape." Customer Trials Worldwide, data centers currently account for approximately 1% of carbon emissions and approximately 1 to 1.5% of electricity consumption. More than 95% of data centers use traditional air- and water-cooling technologies. 2-PIC is the most sustainable, cost-effective, and efficient alternative to traditional air-cooled data centers in terms of energy and water consumption. By submerging electronic equipment directly in a dielectric fluid, they can be cooled efficiently and safely, without the risk of hardware damage. Customer trials of Chemours Opteon™ 2P50 have confirmed outstanding performance. Thermal Stability 2-PIC can reduce data center cooling energy consumption by more than 90% and nearly eliminate water use 2-PIC can reduce data center cooling energy consumption by more than 90% and nearly eliminate water use, reducing operating expenses. In addition, the 2-PIC simplified cooling structure supports reduced capital expenditures by enabling up to a 60% reduction in the physical data center footprint, while ensuring optimum cooling capabilities to support next-generation high-performance computing applications. The ability to reclaim and reuse the two-phase immersion fluid also creates a clear path to a circular economy. “We’re working to create more than just an incremental improvement,” said Duchini, adding “Our vision is to set a new industry standard with the performance and thermal stability of Opteon™ 2P50. In addition to playing a critical role in enabling 2-PIC technologies through enhanced thermal management performance, this new solution from Chemours will enable businesses and entire industries to reduce their physical footprint and environmental impact.” Chemours Opteon™ Products Chemours Opteon™ 2P50 fluid for 2-PIC is aligned with the transition to lower global warming potential (GWP) products. Whether being used in immersion cooling applications, industrial cooling, or throughout the entire cold chain, Chemours Opteon™ products offer a strong sustainability profile, and excellent performance properties across a broad range of applications.

Insights & Opinions from thought leaders at The Chemours Company

“If you don’t like the weather in New England, just wait a few minutes.” To this day, Mark Twain’s quote is used to describe quickly changing weather conditions in regions throughout the United States, United Kingdom, and elsewhere. However, in contrast to the weather, the climate change being experienced globally is creating nontraditional conditions that are much more permanent. Consequently, HVACR systems are being subjected to a new set of conditions that, if not addressed properly, may significantly impact performance, efficiency, and lifespan. Report from Climate Central 75% of the Earth’s land has become permanently drier over the last three decades Consider a few examples. According to a recent report from Climate Central, as a result of climate change, Michigan has nine fewer subfreezing days in winter. The European Union’s Copernicus Climate Change Service reported that the average temperature in the summer of 2024 in Europe was 1.54 C above the average between 1991 and 2020. According to the United Nations Convention to Combat Desertification, 75% of the Earth’s land has become permanently drier over the last three decades, caused in part by declining humidity in some regions. Climate change impacts such as these have made it increasingly important for HVACR contractors to understand the ways new weather-related factors can challenge equipment performance and durability—and to help customers optimize the resiliency of their systems. Three main challenges To follow are insights and tips that can help contractors successfully “weather” three main challenges driven by climate change: extreme heat, high or low humidity, and extreme weather events. As this information demonstrates, no matter how hot, dry, wet, or stormy your region has become, being proactive in system checks and maintenance can help customers’ systems run effectively, minimize repair costs, and ensure equipment operates through its expected lifecycle. Climate-change impact one: extreme heat In extreme heat, parts such as compressors and condensers undergo more than the standard wear From potential leaks to higher energy bills, the need for air conditioners to run longer and harder to achieve desired cooling temperatures as temperatures rise can be literally and figuratively costly to your customer, a building’s occupants, and the environment. In extreme heat, components such as compressors and condensers undergo more than the standard wear and tear. If not properly maintained to meet rigorous demands, equipment may not be able to cool a space adequately. This means it will potentially consume more energy and increase energy bills. Equipment could also overheat, break down, require costly repairs, and reach end of life more quickly. In addition, higher temperatures, longer run times, and increased condensing pressure may lead to more leaks. Take these steps to help HVACR system owners overcome the challenges of extreme heat: Check air filters frequently and replace them as needed. Dust and debris can accumulate quickly in hot, dry weather. Perform comprehensive regular maintenance. This should include cleaning condenser coils and maintaining proper refrigerant levels. Optimize settings. Raising the thermostat slightly when daily temperatures peak can help reduce energy consumption and wear and tear on components. Work with facility managers to ensure proper building insulation. This can reduce heat gain and lessen the burden on air conditioning systems. Create shade for outdoor units and keep them clear of debris. Protection from direct sunlight can help maintain cooler operating temperatures. Climate-change impact two: humidity Indoor comfort and HVACR system performance depend on keeping the right humidity balance Indoor comfort and HVACR system performance depend on maintaining the right humidity balance. When humidity is too low, air is dry and static, leading to discomfort for occupants and potential issues with air quality and system operation. However, if humidity is too high, systems will have to work harder to remove moisture from the air while simultaneously providing the desired level of cooling. Take these steps in high-humidity situations: Keep tabs on moisture buildup and perform regular cleaning of components such as ducts, filters, and evaporator coils. Identifying and removing moisture accumulation can prevent damage from mold or corrosion. Ensure proper insulation of ductwork to help mitigate moisture buildup. Enhance dehumidification systems and make sure they are properly sized to handle specific humidity levels. Check air filters, blowers, condensate drains, and ductwork to ensure proper airflow. In low-humidity situations: Install humidifiers. Consider humidifiers that can be integrated with the heating/cooling system to achieve a consistent level of approximately 30% to 50% relative humidity. Perform regular humidifier maintenance, including cleaning and replacing filters, checking for mineral deposits, and ensuring all lines are clear. Ensure proper insulation of ductwork and seal any leaks. Perform regular maintenance checks of HVACR systems as noted above Climate-change impact three: extreme weather events It’s not unusual for extreme weather events—including intense thunderstorms, snowstorms, and windstorms—to cause power outages and surges, flooding, or high winds, all of which can physically damage HVACR equipment. To avoid system problems or, possibly, total system failure it’s important to assess damage as quickly and thoroughly as possible then implement the necessary repairs or replacements. Be sure in these situations to always prioritize technician safety and, where applicable, to obtain clearance from emergency responders. Take these steps to support system resilience during extreme weather events: Conduct routine maintenance as noted in factors one and two above. Work with facility managers to ensure buildings have proper insulation and weatherproofing. Have emergency backup power sources in place. Ensuring continual operation during power outages is especially important for mission-critical systems. Best practices for routine equipment checkups One final point to consider on this topic is that employing the practices above can help reduce further contributions to the global warming that drives climate change. One example is taking steps to prevent refrigerant leaks. Another is energy conservation that can be achieved by systems that run at optimized efficiency. Even efforts to prolong the lifespan of systems can help decrease the waste of resources and other materials. While “waiting a few minutes” may prevent someone from unnecessarily canceling a ballgame or picnic on account of rain, the HVACR industry needs to address the challenges of climate change “without delay” and for the foreseeable future. Continuing best practices for routine equipment checkups and maintenance, increasing system checks in climates that have become hotter, drier, wetter, or stormier than usual; and employing some new techniques can all work together to ensure resilient systems, satisfied customers, and a healthier planet.

The COVID-19 pandemic has significantly impacted how we view indoor air quality and HVAC systems. Consequently, HVAC systems have undergone several improvements in the post-pandemic world. Systems today tend to have better filtration, increased ventilation, and advanced air-cleaning technologies, such as UV-C light and bipolar ionization. We asked our Expert Panel Roundtable: How have HVAC systems improved (including better indoor air quality) in the post-pandemic world?

Data centers worldwide are under intense pressure. High-powered computing is a global necessity that seemingly gets more demanding by the day. There’s also the need to prioritize sustainability improvements ranging from resource conservation to decarbonization. And data centers must consider their bottom line and remain competitive. Anticipating the challenges data centers will continue to face, scientists and engineers have innovated two-phase (2-PIC) immersion cooling. With the capacity to meet the elevated cooling requirements driven by high-powered computing, this next-generation solution delivers on environmental priorities by significantly lowering data center energy consumption, slashing, if not eliminating, water use, while supporting decarbonization, circularity missions, and more. Emergence of 2-PIC Traditional approaches are fast approaching capacity for meeting current and future cooling needs The emergence of 2-PIC comes at a critical time, because the traditional cooling methods that have kept data centers up and running so far—namely air cooling and water cooling—are doing so at the detriment of the planet. Additionally, these traditional approaches are quickly approaching capacity for meeting current and future cooling needs. Air- and water-cooling methods are used in approximately 95% of the estimated 8,000 data centers that exist today. The criticality of high-powered computing Once seen as a future need, high-powered computing, and faster-than-ever processing are now established as critical to the operation of businesses, governments, organizations, and other entities that support the way communities function, survive, and thrive. Whether it’s health and wellness, financial institutions, economic growth, safety and protection, entertainment, education, or any other service supporting our way of life, successfully providing that service fully depends on the ability of data centers to quickly and reliably obtain, store, and process data. Influence of AI AI has a profound influence and, generates far more power than traditional internet uses Moreover, when we say “data centers,” we’re not just speaking of big players like Microsoft, Google, Meta, and Amazon. Equally dependent on high-performance, high-speed computing are enterprise data center operators, such as our governments and military, financial institutions, healthcare systems, educational institutions, and more. We also must acknowledge the profound influence of artificial intelligence (AI), which generates far more power than traditional internet uses. Its effects are far-reaching, enhancing patient care, supporting risk management and fraud detection in finance, boosting crop yields within agriculture, and more. The environmental costs of data centers According to the latest estimates by the International Energy Agency, data centers worldwide produce 1% of energy-related carbon emissions and in 2022 used approximately 460 TWh of electricity per year—equating to 2% of global electricity demand. McKinsey and Company estimates 40% of this electricity is used for data center cooling. Data centers’ impact on the environment also includes their significant water consumption, averaging 300,000 gallons per day, and a physical footprint that averages 100,000 square feet but in the case of some hyperscale data centers can range between 1.3 to 2 million square feet. In terms of growth, a U.S. market report from Newmark tells us that in the U.S. alone, the U.S. data center footprint will absorb 35 gigawatts by 2030, which is more than twice the data center power consumption of 2022. The emergence of liquid cooling: the elevated interest in 2-PIC From reducing energy and water consumption to shrinking physical footprints, 2-PIC offers the planet a better data center solution. In less than two years, traditional cooling systems won’t be able to support the exponential growth in the world’s data processing and storage applications. Based on publicly available product roadmaps from major chip manufacturers, by 2026, air-cooled systems will no longer be able to meet the cooling needs of most next-generation, high-performance computing chips. Capable of removing heat more effectively than air cooling, liquid cooling uses a liquid such as water or a dielectric fluid to cool the heat-generating components of servers. The liquid can cool these components directly, or it can be done indirectly through a heat exchanger. With two-phase immersion cooling the entire server rack is submerged in a tank filled with a dielectric fluid. Single-phase and two-phase liquid cooling Single-phase liquid cooling uses a pump to circulate the liquid through a closed-loop system Single-phase liquid cooling uses a pump to circulate the liquid through a closed-loop system. Two-phase liquid cooling uses a phase-change material, such as a refrigerant, which evaporates and condenses as it absorbs and releases heat. With 2-PIC, which is a form of two-phase liquid cooling, the entire server rack is submerged in a tank filled with dielectric fluid. The fluid boils as it’s heated by the components of the servers, creating bubbles that rise to the surface and condense in a heat exchanger. Gravity then returns the condensed fluid to the tank, creating a natural circulation loop that does not require pumps or fans. Advantages of 2-PIC 2-PIC is commanding attention as the solution for meeting the cooling demands of the high-powered computing components of today and tomorrow. Moreover, the technology of 2-PIC systems, combined with the right dielectric fluid, delivers advantages to “take the heat off” data centers. Here’s a breakdown of additional 2-PIC benefits: Up to 90% reduction in energy consumption: Based on modeling completed by the industry, 2-PIC is expected to reduce up to 90% of data center cooling energy consumption and 40% of overall data center energy consumption*. (*Compared to traditional air-cooling technologies) Enhanced computing performance and data center reliability: 2-PIC allows servers to operate at higher temperatures and power densities, while reducing the risk of overheating. Significant reduction in water consumption: Depending on the data center location and cooling design methodology, water consumption could even be eliminated completely. 60% reduction in the physical footprint: 2-PIC reduces the space required for cooling equipment, freeing up more floor area for servers and increasing the rack density of the data center. Lower GWP and circularity: Chemours Opteon™ 2P50 is a developmental dielectric heat-transfer fluid, currently pre-commercial, pending regulatory approval. It offers an extremely low global warming potential (GWP) of 10 and was specifically created to optimize the performance of the electronic components in a 2-PIC system. This 2-PIC fluid also enables the reprocessing/reuse of existing fluid to maximize circularity. The bottom line: In addition to other compelling data, a recent study commissioned by Chemours and LiquidStack through Syska Hennessy, revealed that, compared with other state-of-the-art liquid cooling methods, 2-PIC can deliver up to a 40% lower total cost of ownership (TCO) and significantly reduce operational expenditures (OPEX), with savings ranging from 54% to 88.6%. Benefits of new data center cooling technologies compared to single-phase direct-to-chip, and single-phase immersion methods. 2-PIC, the future-ready solution As the world’s reliance on AI and other high-powered computing capabilities escalates, data center cooling solutions must grow with demand while significantly reducing their impact on the environment. In global energy savings alone, 2-PIC could generate an estimated savings of 340 TWh by 2055—the equivalent of powering more than 517 million laptops 24/7. And even with increasing IT loads, 2-PIC maintains its performance, ensuring long-term cost-effectiveness and adaptability to meet future demands. With society at a crossroads between the criticality of high-powered computing and a planet in crisis, the industry is turning its attention to 2-PIC as the solution for today and tomorrow.

From A To L: Your A2L Transition Guide

DownloadLeveraging Radiant And Hydronics To Help Achieve Decarbonization Goals

DownloadSealed Connectors In Harsh Environments

DownloadPowering And Cooling Next Generation Data Centers

DownloadDebunking Myths To Promote A Bright Future For Heat Pumps

Download