NevadaNano - Experts & Thought Leaders

Latest NevadaNano news & announcements

Karl Roberts is a B.A. (Hons) Business Administration graduate based in Liverpool, UK. For the past five years, Karl has been at MSA Bacharach with two years of this time in the role of Sales Director, with budget & senior management responsibility for the European and US fixed detection sales teams. Prior roles have included the UK and European Sales Management at Scott Safety/Tyco Gas & Flame Detection and A1-CBISS. Karl brings over 17 years of combined experience within the HVAC/R market, driving product development, specification, and sales to end-users, integrators, contractors & OEMs across food retail, hospitality, and cold chain (processing, storage & distribution, transportation). Industrial safety markets Combined with experience within the industrial safety markets (POG, chemical, food & beverage, pharmaceutical, manufacturing), Karl brings an understanding of a broad range of sensor technologies, including IR, PAIR, pellistor, UV, Ultrasonics, electrochemical, and MOS. He is an Associate Member of the Institute of Refrigeration, representing as an expert in refrigerant detection within the British Refrigeration Association working groups. “We are very excited to be adding Karl to the NevadaNano team. His extensive industry and sales and marketing experience within the HVAC/R market is a huge asset to our aggressive growth strategies,” said Gary Collins, VP of Sales and Marketing, Nevada Nano.

NevadaNano, the innovator in gas detection sensor technology, announced that Naren Prasad joined the company to guide the Hardware enabled SaaS products to reduce methane emissions. Naren will serve as Chief Product Architect and Delivery Officer. “As one of the original developers and innovators of the Advanced Metering Infrastructure industry, Naren has a long history of enabling disruptive transformation in the IoT world,” said Ralph Whitten, CEO of NevadaNano. New business strategies “He will be a tremendous asset to NevadaNano as we continue to drive innovation in the gas sensing industry, by providing products to reduce methane and refrigerant emissions worldwide.” Naren brings nearly 30 years of experience to NevadaNano during which he worked in software development for both new and established companies. Throughout his career, he has led product development teams to define new business strategies and initiatives and deliver pioneer products. He has held leadership roles for market pioneers including Landis+Gyr, eMeter Corporation (now part of Siemens), and CellNet Data Systems (acquired by Schlumberger). He holds a patent for Message-Bus-Based Advanced Meter Information System with Applications for Cleaning, Estimating, and Validating Meter Data. Naren earned his B. Tech CSE from the National Institute of Technology Tiruchirappalli, India.

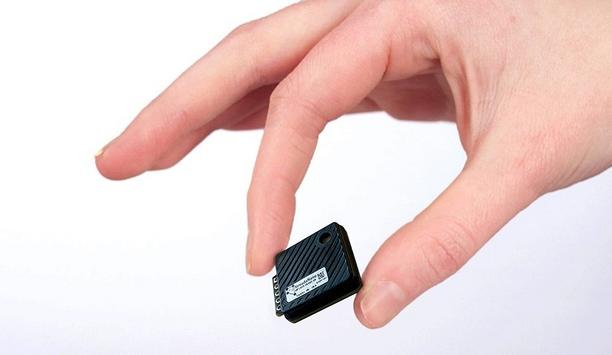

NevadaNano, the globally renowned innovator in gas detection sensor technology, has announced its partnership with Emerson, to jointly develop refrigerant gas detector products, which will provide a solution to the heating, ventilation, air conditioning and refrigeration (HVACR) industry, for refrigerant leak detection. NevadaNano - Emerson partnership “We are proud to partner with Emerson to develop essential solutions that can help lower the impact of existing HVACR equipment on the global environment and facilitate the safe use of low GWP refrigerant gases,” said Ralph Whitten, the Chief Executive Officer (CEO) of NevadaNano. MPS technology is a patented platform, which is programmable for a range of A1, A2L, and A3 refrigerant gases NevadaNano’s Molecular Property Spectrometer (MPS) technology, together with Emerson’s renowned HVACR technologies experience, including flammable gas sensing products, creates a strong leadership position for gas sensing solutions. The MPS technology is a patented platform, which is programmable for a wide range of A1, A2L, and A3 refrigerant gases, such as R32, R454, and R407. Switching to lower GWP refrigerants “Our solution enables original equipment manufacturers to have their product line compliant with federal HFC phasedown regulations, known as the AIM act,” said John Rhodes, Group President for Digital & Connected Technologies at Emerson, adding “The mandate shifts the industry from high GWP to lower GWP refrigerants, including mildly flammable A2L refrigerants.” NevadaNano’s MPS outperformed all other technologies in the Air Conditioning, Heating, & Refrigeration Institute (AHRI) study (Project 9014), which was published on August 13, 2021. The study incorporates 28 test requirements from UL, IEC, ASHRAE15, and the JRA regulatory agencies. Emerson gas detector The combined ‘lab on a chip’ allows the sensor to pass all tests, including vibration and resistance to condensing environments and poisoning chemicals. The Emerson gas detector will allow the HVACR industry to deploy smarter A2L systems.

Insights & Opinions from thought leaders at NevadaNano

Society is prioritizing the mitigation of climate change, and new, potentially flammable, low-Global Warming Potential (GWP) refrigerants are a key tool in broadly lowering the rate of global warming. The detection of fugitive (leaking) refrigerant is a new regulation emerging as HVAC equipment manufacturers convert to low-GWP refrigerants. Both A2L and A3 low-GWP refrigerants, while climate-friendly, are flammable. As such, OEMs will have to integrate refrigerant sensors that detect leaked refrigerant that could potentially cause a harmful event. Gas detection sensors Refrigerant gas sensors quickly detect gases before they reach explosive levels and alert users to the need for mitigation. Commercial buildings and medium-to-large residential units have the most essential need and gain the most benefit from detecting gases at pre-flammable levels. Gas detection sensors have been used for decades in other applications, such as industrial safety and home monitoring. Adding the right sensing technology to HVAC equipment will not be a significant burden to most businesses and homeowners. As a general rule, the better and more robust the technology, the less maintenance needed over a long lifespan, and the lower the total cost of ownership (TCO) for the systems. Property management companies Legacy technologies have shortcomings that limit their performance, according to NevadaNano Meeting the need in the market is the MPS refrigerant sensor from NevadaNano, a sensor engineered specifically for the detection of harmful refrigerants within HVAC equipment. Legacy technologies have shortcomings that limit their performance, according to NevadaNano. In contrast, the MPS is designed for a 10-plus year life, is immune to poisoning, and never requires re-calibration. “Since the MPS is a smart sensor module, it performs a self-test every two seconds and immediately reports a fault or a condition if it ever operates out of normal parameters,” says Bob Christensen, NevadaNano’s Senior Director of Business Development. NevadaNano is actively engaged with HVAC equipment providers to integrate and optimize the ability to detect leaked refrigerant quickly and accurately. “As A2L refrigerants become the standard, it’s critical that businesses, property management companies, and homeowners can be confident that their facilities are safe,” says Christensen. Eventual replacement sensors “In addition, our sensors remove the burden and uncertainty associated with legacy technology and faulty sensors.” Legacy nondispersive infrared sensor (NDIR) and pellistor technologies often require human intervention to work properly and require frequent re-calibration and eventual replacement sensors. These traditional sensor technologies require frequent tests to verify that they are operational and able to detect refrigerant gas within specification. In this bump test, a technician introduces a known volume of gas and verifies the sensor works within proper safety parameters. If the sensor does not read the gas correctly, the sensor may be corrected or recalibrated. However, most sensors’ performance decays over time, and will need to be replaced. NevadaNano’s MPS does not require field-testing or re-calibration, an advantage over traditional sensor technology, says Christensen.

Leveraging Radiant And Hydronics To Help Achieve Decarbonization Goals

DownloadSealed Connectors In Harsh Environments

DownloadPowering And Cooling Next Generation Data Centers

DownloadDebunking Myths To Promote A Bright Future For Heat Pumps

DownloadOptimizing Comfort: The Ultimate HVAC Component Guide

Download