Microsoft - Experts & Thought Leaders

Latest Microsoft news & announcements

Carrier Global Corporation, the global pioneer in intelligent climate and energy solutions, was awarded the World Environment Center's (WEC) 40th Annual Gold Medal for International Corporate Achievement in Sustainable Development. Past award winners of the global competition include Microsoft, Walmart, IBM, and Starbucks. commitment to sustainability "Carrier is honored to be recognized by the prestigious World Environment Center for our progress and commitment to sustainability," said Carrier Chairman & CEO, David Gitlin, adding "We are strategically innovating and expanding our portfolio of solutions through electrification, energy efficiency, and digitally enabled lifecycle solutions to help our customers avoid more than one gigaton of carbon emissions by 2030." He continues, "At Carrier, our 50,000 team members remain committed to pushing the boundaries of what is possible and setting new standards for sustainable development." innovative, energy-efficient solutions The award was presented to Carrier's Chairman & CEO David Gitlin at WEC's Gold Medal Presentation Ceremony The award was presented to Carrier's Chairman & CEO - David Gitlin at WEC's Gold Medal Presentation Ceremony in Washington, D.C., on Nov.13, 2024, by Chairman and CEO of GE Aerospace, H. Lawrence Culp, Jr. "I am pleased to see David and the Carrier team receive this prestigious award," said Mr. Culp, adding "Carrier's dedication to shaping a more sustainable future and its ongoing investments in innovative, energy-efficient solutions is raising the bar in climate leadership." He continues, "On the heels of its successful portfolio transformation, Carrier's pioneering role in driving sustainable progress in its operations, for its customers, and across the entire industry is both inspiring and admirable." climate and energy technologies WEC President and CEO - Margaret O'Gorman, stated, "Congratulations to Carrier on being selected as the 2024 Gold Medal winner in recognition of their steadfast commitment to breakthrough climate and energy technologies and progress toward their 2030 sustainability goals." Margaret O'Gorman adds, "We look forward to Carrier's continued global climate leadership in empowering customers with innovative, sustainable solutions." sustainability in business practices The World Environment Center's Gold Medal for International Corporate Achievement in Sustainable Development, awarded annually since its establishment in 1985, honors a global company that has integrated sustainability into its business practices, created ground-breaking solutions to critical environmental and social challenges, and demonstrated global leadership to accelerate progress toward a sustainable future. An independent Gold Medal Jury comprised of recognized sustainability experts, including international pioneers from academia, government, non-governmental organizations, and retired industry professionals, selects the Gold Medalist through a global competition among nominated companies invited to apply for the Award.

Big Ass Fans and Lexmark have partnered to deliver the next generation of full-facility comfort for frontline industrial and manufacturing workers with the introduction of Big Ass Fans’ CommandSense, the first-ever fully automated, Internet of Things (IoT)-powered comfort ecosystem designed to reduce heat stress while improving worker safety and lowering energy costs for industrial facilities. For 25 years, Big Ass Fans has led the industrial comfort industry with premium, innovative products that provide best-in-class comfort in complex environments. Requirements for worker safety Following the hottest summer ever recorded, CommandSense presents a never-before-seen solution for industrial facilities to manage rising temperatures and help meet evolving state requirements for worker safety — all while addressing concerns around cost, infrastructure, and sustainability. “At Big Ass Fans, our goal is to provide comfort without compromise,” said Ken Walma, president and CEO of Big Ass Fans. “CommandSense represents a new era for this mission. We’re proud to bring this automatic comfort and cooling solution to frontline associates and take worker safety to the next level.” Unparalleled comfort control Powered by Lexmark and Microsoft, CommandSense joins Lexmark brains with Big Ass brawn Powered by Lexmark and Microsoft technology, CommandSense merges Lexmark brains with Big Ass brawn. CommandSense continuously monitors occupancy, humidity, temperature, and other facility conditions to automatically adjust fans, heaters, and ventilation fans for unparalleled comfort control. “Innovation is so exciting to watch,” said Demetrios Karathanasis, IoT portfolio director for Lexmark. “The Lexmark team is thrilled to provide the foundational technology that has allowed Big Ass Fans to make the leap from manufacturing exceptional products to offering comfort without compromise through CommandSense.” CommandSense system Each CommandSense system is uniquely designed for its facility, providing customized comfort control for small- to medium-sized manufacturing operations and untapped potential for even larger facilities. Using a proprietary solution composed of edge computing, an IoT platform, environmental sensors, device protocol translation, and other advanced technology, CommandSense delivers fully integrated comfort like never before. In addition to providing unmatched cooling and efficiency, CommandSense also: Improves employee morale and productivity by mitigating heat stress by up to 60% and boosting employee productivity by up to 50% when paired with Big Ass fans and heaters. Provides robust monitoring and automatic alerts when system components encounter functional errors. Uses four times less energy than HVAC and at a fraction of the cost, producing savings up to USD 1 million over five years. CommandSense will be available in April 2025.

A new research report from the IoT analyst firm Berg Insight says that annual shipments of wireless devices for industrial automation applications reached 10.7 million units worldwide in 2023, accounting for approximately 9 percent of all new connected nodes. Growing at a compound annual growth rate (CAGR) of 12.3 percent, annual shipments are expected to reach 19.1 million by 2028. The installed base of wireless devices in industrial automation reached at the same time 56.5 million in 2023. While wired networking solutions are still predominantly used for industrial communications between sensors, controllers and systems, wireless solutions have gained a strong foothold in a number of applications. Non-mission critical applications Wireless solutions are used in hard-to-reach locations or hazardous areas where wired solutions are impractical, ineffective or cost-prohibitive. In factory automation, wireless solutions are widely used to connect mobile industrial equipment such as automated guided vehicles and to remotely access machines for programming and servicing. In factory automation, wireless solutions are widely used to connect mobile industrial equipment In process automation, wireless technologies are increasingly used in non-mission critical applications to remotely monitor and optimise processes while also ensuring worker safety. Today, a growing number of wireless field devices are provided by many major industrial automation vendors including ABB, Emerson, Hitachi, Honeywell, OMRON, Schneider Electric, Siemens and Yokogawa. Remote monitoring applications Wi-Fi has emerged as the most widely used wireless technology in industrial environments largely due to the wide availability of compatible hardware. Providers of industrial Wi-Fi devices include Siemens, Cisco, Belden, Moxa, Phoenix Contact, HMS Networks and Advantech. The 802.15.4-based protocol WirelessHART is the second largest wireless technology used in field devices. The technology is widespread in remote monitoring applications for process industries. Emerson became the first company to market WirelessHART products in 2008 and has today an installed base of more than 10 million wireless pressure transmitters. Industrial automation market Cellular solutions are typically used for data acquisition and backhaul communications Cellular solutions are typically used for data acquisition and backhaul communications in distributed automation applications. The largest providers of cellular IoT gateways and routers in the industrial space include Semtech, Cisco, Digi International, Moxa, GE Vernova, HMS Networks, Robustel, InHand Networks and Teltonika Networks. Devices featuring Wi-Fi, WirelessHART and cellular connectivity accounted for 70 percent of the installed base in 2023. “Partnerships and collaborations between industrial automation players and technology companies are increasingly focused on artificial intelligence,” said Veronika Barta, IoT Analyst at Berg Insight. During 2023–2024, the industrial automation market witnessed both the emergence of new partnerships as well as the extension of existing collaborations focusing on AI. AI-powered industrial solutions For instance, both ABB and Siemens extended their respective partnerships with Microsoft to focus on generative AI applications in digital solutions. In addition, both Schneider Electric and Siemens have partnerships with NVIDIA to advance the use of AI-powered industrial solutions. Most recently in June 2024, Rockwell Automation announced a collaboration with NVIDIA to scale the use of AI in industrial mobile robots. “More collaborations and partnerships can be expected in the coming years as solution providers bet on AI to optimise industrial processes,” concluded Ms. Barta.

Insights & Opinions from thought leaders at Microsoft

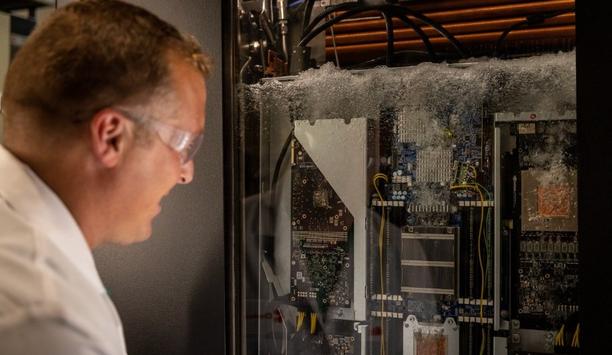

Data centers worldwide are under intense pressure. High-powered computing is a global necessity that seemingly gets more demanding by the day. There’s also the need to prioritize sustainability improvements ranging from resource conservation to decarbonization. And data centers must consider their bottom line and remain competitive. Anticipating the challenges data centers will continue to face, scientists and engineers have innovated two-phase (2-PIC) immersion cooling. With the capacity to meet the elevated cooling requirements driven by high-powered computing, this next-generation solution delivers on environmental priorities by significantly lowering data center energy consumption, slashing, if not eliminating, water use, while supporting decarbonization, circularity missions, and more. Emergence of 2-PIC Traditional approaches are fast approaching capacity for meeting current and future cooling needs The emergence of 2-PIC comes at a critical time, because the traditional cooling methods that have kept data centers up and running so far—namely air cooling and water cooling—are doing so at the detriment of the planet. Additionally, these traditional approaches are quickly approaching capacity for meeting current and future cooling needs. Air- and water-cooling methods are used in approximately 95% of the estimated 8,000 data centers that exist today. The criticality of high-powered computing Once seen as a future need, high-powered computing, and faster-than-ever processing are now established as critical to the operation of businesses, governments, organizations, and other entities that support the way communities function, survive, and thrive. Whether it’s health and wellness, financial institutions, economic growth, safety and protection, entertainment, education, or any other service supporting our way of life, successfully providing that service fully depends on the ability of data centers to quickly and reliably obtain, store, and process data. Influence of AI AI has a profound influence and, generates far more power than traditional internet uses Moreover, when we say “data centers,” we’re not just speaking of big players like Microsoft, Google, Meta, and Amazon. Equally dependent on high-performance, high-speed computing are enterprise data center operators, such as our governments and military, financial institutions, healthcare systems, educational institutions, and more. We also must acknowledge the profound influence of artificial intelligence (AI), which generates far more power than traditional internet uses. Its effects are far-reaching, enhancing patient care, supporting risk management and fraud detection in finance, boosting crop yields within agriculture, and more. The environmental costs of data centers According to the latest estimates by the International Energy Agency, data centers worldwide produce 1% of energy-related carbon emissions and in 2022 used approximately 460 TWh of electricity per year—equating to 2% of global electricity demand. McKinsey and Company estimates 40% of this electricity is used for data center cooling. Data centers’ impact on the environment also includes their significant water consumption, averaging 300,000 gallons per day, and a physical footprint that averages 100,000 square feet but in the case of some hyperscale data centers can range between 1.3 to 2 million square feet. In terms of growth, a U.S. market report from Newmark tells us that in the U.S. alone, the U.S. data center footprint will absorb 35 gigawatts by 2030, which is more than twice the data center power consumption of 2022. The emergence of liquid cooling: the elevated interest in 2-PIC From reducing energy and water consumption to shrinking physical footprints, 2-PIC offers the planet a better data center solution. In less than two years, traditional cooling systems won’t be able to support the exponential growth in the world’s data processing and storage applications. Based on publicly available product roadmaps from major chip manufacturers, by 2026, air-cooled systems will no longer be able to meet the cooling needs of most next-generation, high-performance computing chips. Capable of removing heat more effectively than air cooling, liquid cooling uses a liquid such as water or a dielectric fluid to cool the heat-generating components of servers. The liquid can cool these components directly, or it can be done indirectly through a heat exchanger. With two-phase immersion cooling the entire server rack is submerged in a tank filled with a dielectric fluid. Single-phase and two-phase liquid cooling Single-phase liquid cooling uses a pump to circulate the liquid through a closed-loop system Single-phase liquid cooling uses a pump to circulate the liquid through a closed-loop system. Two-phase liquid cooling uses a phase-change material, such as a refrigerant, which evaporates and condenses as it absorbs and releases heat. With 2-PIC, which is a form of two-phase liquid cooling, the entire server rack is submerged in a tank filled with dielectric fluid. The fluid boils as it’s heated by the components of the servers, creating bubbles that rise to the surface and condense in a heat exchanger. Gravity then returns the condensed fluid to the tank, creating a natural circulation loop that does not require pumps or fans. Advantages of 2-PIC 2-PIC is commanding attention as the solution for meeting the cooling demands of the high-powered computing components of today and tomorrow. Moreover, the technology of 2-PIC systems, combined with the right dielectric fluid, delivers advantages to “take the heat off” data centers. Here’s a breakdown of additional 2-PIC benefits: Up to 90% reduction in energy consumption: Based on modeling completed by the industry, 2-PIC is expected to reduce up to 90% of data center cooling energy consumption and 40% of overall data center energy consumption*. (*Compared to traditional air-cooling technologies) Enhanced computing performance and data center reliability: 2-PIC allows servers to operate at higher temperatures and power densities, while reducing the risk of overheating. Significant reduction in water consumption: Depending on the data center location and cooling design methodology, water consumption could even be eliminated completely. 60% reduction in the physical footprint: 2-PIC reduces the space required for cooling equipment, freeing up more floor area for servers and increasing the rack density of the data center. Lower GWP and circularity: Chemours Opteon™ 2P50 is a developmental dielectric heat-transfer fluid, currently pre-commercial, pending regulatory approval. It offers an extremely low global warming potential (GWP) of 10 and was specifically created to optimize the performance of the electronic components in a 2-PIC system. This 2-PIC fluid also enables the reprocessing/reuse of existing fluid to maximize circularity. The bottom line: In addition to other compelling data, a recent study commissioned by Chemours and LiquidStack through Syska Hennessy, revealed that, compared with other state-of-the-art liquid cooling methods, 2-PIC can deliver up to a 40% lower total cost of ownership (TCO) and significantly reduce operational expenditures (OPEX), with savings ranging from 54% to 88.6%. Benefits of new data center cooling technologies compared to single-phase direct-to-chip, and single-phase immersion methods. 2-PIC, the future-ready solution As the world’s reliance on AI and other high-powered computing capabilities escalates, data center cooling solutions must grow with demand while significantly reducing their impact on the environment. In global energy savings alone, 2-PIC could generate an estimated savings of 340 TWh by 2055—the equivalent of powering more than 517 million laptops 24/7. And even with increasing IT loads, 2-PIC maintains its performance, ensuring long-term cost-effectiveness and adaptability to meet future demands. With society at a crossroads between the criticality of high-powered computing and a planet in crisis, the industry is turning its attention to 2-PIC as the solution for today and tomorrow.

Johnson Controls’ Advanced Development Engineering Center (JADEC) in New Freedom, PA., about 25 miles from Philadelphia, highlights and demonstrates the company’s capabilities related to development, testing and manufacturing. The 357,000-square-foot facility is an advanced engineering and testing facility for water-cooled chillers, air-cooled chillers, air handlers, compressors, and heat pumps. Much of the development in the facility centers on advancements in a critical vertical market for the HVAC industry – data centers. Big challenge Data centers are a big challenge – and a huge opportunity – for the HVAC industry. “You cannot ignore the tremendous growth opportunity in this vertical,” says Todd Grabowski, president, Global Data Center Solutions for Johnson Controls. Unlike other verticals that are more dominant in certain geographic regions, data centers are growing everywhere globally – and at a breathtaking pace. “As a growth company, it is critical that we have solutions to handle the growth and serve the customers in the data center market,” says Grabowski. Performance of various components Testing options at JADEC include testing the performance of various components Testing options at JADEC include the ability to test the performance of various components in a controlled environment that approximates how they will operate in the customer’s real-world setting. There are more than 20 testing labs available at the JADEC campus, covering some 250,000 square feet. “We want everyone to understand the unique position Johnson Controls is in to use our technology and our manufacturing scale to accomplish desired outcomes,” said Grabowski. Non-compressor solution JADEC displays the full breadth of what they offer, including a non-compressor solution using direct evaporative cooling and an air-cooled unit that uses a screw compressor or a magnetic-bearing centrifugal compressor. Also included are various water-cooled chillers. Johnson Controls owns, develops, tests, and manufactures all the compressors on display. Customers are assured of getting a fully engineered and supported solution from Johnson Controls (e.g., no third-party compressors). Johnson Controls owns, develops, tests, and manufactures all the compressors on display. Colocated data centers Grabowski emphasizes that each customer installation has site-specific needs that require unique solutions that Johnson Controls seeks to fulfill. The company works closely with data centers, including those operated by “hyperscalers” such as Amazon, Microsoft, Apple, and Meta, and colocated data centers that rent space and capacity to customers based on their growth and needs. Colocated data centers come in a variety of sizes and types; some of them are operated by companies such as Equinix and NTT. Data center solutions Sustainable methods include the use of refrigerants with ultra-low GWP The sustainability of data center solutions is a bigger issue than ever, given the sheer volume of data centers being built to handle the world’s growing computational needs. Sustainable approaches include the use of refrigerants with ultra-low GWP, and water-free systems that do not require higher costs or create higher demands on a locality’s water infrastructure. Magnetic bearing centrifugal compressors are more energy-efficient because no friction is lost in the compression; also, the equipment is quieter. Impact on global electricity demand “Sustainability has always been an important aspect, and now it is critical in 2024 and beyond,” says Grabowski. Because data centers are huge consumers of energy, they can put more strain on the electricity grid and have a big impact on global electricity demand. Lowering energy usage helps to address the challenge. “We want to contribute to energy efficiency, be good stewards of water, and reduce noise,” says Grabowski. Increasing the challenges are the proliferation of new artificial intelligence (AI) chips, more common in newer data centers, which need more power and create more heat than older chips. Advantages of water cooling The liquid contained in a cold plate on top of the chip is denser than air and accept more transferred heat Closed-loop liquid systems are used to cool individual chips, an application that does not cause a strain on local water supplies. The liquid contained in a cold plate on top of the chip is denser than air and can accept more transferred heat. However, chillers and cooling towers lose water through evaporation and can strain local water supplies. Johnson Controls is researching and testing systems that provide the advantage of water cooling without losing excess water to evaporation. Air-cooled systems In contrast, air-cooled systems can cool chips to a point, but may not provide enough cooling for high-density chips. Johnson Controls provides air-cooled machines up to 600 tons and water-cooled systems up to 4,000-plus tons. “As chip technology evolves, the way you cool, secure and automate the entire data center changes as well,” says Grabowski. “Companies such as Johnson Controls must keep up with evolving trends and provide unique solutions.” As chips become denser from a heat-generation perspective, systems must be optimized from a footprint and energy standpoint. JCI provides air-cooled machines up to 600 tons and water-cooled systems up to 4,000-plus tons. Technological solutions “As chip density increases, we will have technological solutions ready for the next generation of chips when they come out,” adds Grabowski. Johnson Controls is also involved in developing new approaches to managing the heat from data centers, such as the possibility of recapturing the heat and circulating it into a district-heating system for a nearby community, university, or hospital. A more widely deployed approach in Europe, the concept of district heating is gaining acceptance in the U.S. market. {##Poll1725623180 - What is the biggest challenge the data center market presents to the HVAC community?##}

HVAC systems typically operate on a schedule. Heating, cooling and ventilation systems start and stop at fixed times of the day, scheduled around when and how a building is used. But, shouldn’t the number of occupants in a building or a room have an impact on how the HVAC system operates? Considering occupancy, when addressing HVAC needs, is an especially timely approach, given that building schedules are less predictable now, since the COVID-19 pandemic changed work patterns, possibly forever. ‘Hybrid’ work arrangements mean employees could be working or not, at various times of the day or night, no longer adhering to the traditional 9 am to 5 pm workday. Operation of HVAC systems should be just as flexible. Nomad Go Nomad Go uses ‘edge computer vision’ sensors to count the people in a room and provides that data to the Cloud Occupancy represents a key variable, when determining HVAC requirements and a system called Nomad Go enables an HVAC system to operate based on occupancy. Nomad Go uses ‘edge computer vision’ sensors to count the people in a room and provides that data to the Cloud, where it is used to direct operation of a building’s (or a room’s) HVAC system in real time, based on occupancy. “Combining computer vision with artificial intelligence provides a balance between saving energy and ensuring comfort,” said David Greschler, the Chief Executive Officer (CEO) and Co-Founder of Nomad Go. Impact of HVAC systems on carbon emissions He adds, “The system also emerges at a time of greater awareness about climate change and the impact of building HVAC systems on carbon emissions. The stars have aligned to make the solution we have developed very powerful.” Occupancy data is captured using the low-cost computer vision sensors, manufactured by Sony. Each sensor captures video data at 30 frames per second and uses computer vision processing to determine occupancy. Inference analysis occurs inside the device (at the edge). All video is captured anonymously, no individual is identified and video does not leave the sensor. Computer vision sensors David Greschler adds, “Computer vision sensors provide absolute precision and are ten times more accurate than other means of sensing occupancy. Computer vision is the only solution that gives you the precision you need for HVAC. The sensors employ ‘hyper-local learning’, that is, intelligence at the edge continuously improves the device’s accuracy.” In addition to occupancy information to drive the HVAC system, computer vision can also sense other factors, including mask or hard-hat compliance. This added functionality can be provided to Nomad Go customers. Fine-tuning HVAC system operation Fine-tuning HVAC system operation to conform to occupancy data also requires consideration of variables Fine-tuning HVAC system operation to conform to occupancy data also requires consideration of variables, such as how much time it takes to adjust a room to a required comfort level and how hot or cold an empty room is allowed to reach. “What we are really doing is widening the set points in unoccupied mode and narrowing the set points in occupied mode,” said David Greschler. At 1 am, for example, the system would allow room temperature in unoccupied mode to drift, but not so far as to require too long to return to the occupied comfort level. Factors impacting these variables include the outside weather, the time of year, the number of people involved, etc. “We look at how fast it takes for the room to go from unoccupied to occupied set points,” said David Greschler, adding “If it takes less time, we can widen the set points. We are constantly monitoring based on real data. We are saving money in unoccupied mode, but we need to quickly return to a comfortable temperature, if someone enters the room. We also constantly poll the ‘time to comfort’, to adjust the unoccupied temperatures, to ensure a rapid return to comfort.” Occupancy information processing in the Cloud Processing of occupancy information occurs in the Cloud and the system depends on technologies, such as Power over Ethernet (PoE) and WiFi. The system can communicate with building automation systems (BAS) too, in effect injecting occupancy as a new variable in building systems. Alternatively, it can communicate directly with a smart thermostat, such as Nest. The Microsoft Azure cloud platform provides resiliency to the system and Microsoft’s strong Internet of Things (IoT) management tools facilitate the exchange of IoT data with devices. The system also integrates easily with other systems. For example, it can work with Microsoft Outlook calendar software, so as to manage when rooms are likely to be occupied, based on what meetings are planned. Nomad Go operations similar to Nest smart thermostat Nomad Go substitutes occupancy data from computer vision for the smartphone location signal David Greschler compares Nomad Go’s use of occupation data to how a Nest smart thermostat can adjust a home owner’s HVAC system, based on location data from a smartphone. When an occupant (and his or her smartphone) is away from home, the Nest system operates in ‘economy mode’ and then cranks up the system, when the occupant returns home. For the commercial and multi-family environment, Nomad Go substitutes occupancy data from computer vision for the smartphone location signal. (Nomad Go is used in common areas of multi-family residential spaces.) Environmental benefits contribute to ROI “The system involves a monthly subscription fee, which is offset by a likely reduction in energy usage of 30%,” said David Greschler. With the broader trend toward net-zero emissions and large carbon footprint of buildings, environmental benefits also contribute to return on investment (ROI).

Leveraging Radiant And Hydronics To Help Achieve Decarbonization Goals

DownloadSealed Connectors In Harsh Environments

DownloadPowering And Cooling Next Generation Data Centers

DownloadDebunking Myths To Promote A Bright Future For Heat Pumps

DownloadOptimizing Comfort: The Ultimate HVAC Component Guide

Download