As environmental regulations become increasingly stringent, the HVAC/R industry is turning to sustainable refrigerants to minimize environmental impact.

A3 refrigerants—flammable gases with low global warming potential (GWP)—are emerging as a preferred choice. However, their adoption introduces additional regulatory requirements.

EPA regulations

To address these challenges, the industry is leveraging innovative solutions like enhanced small-diameter copper tubes, which enable compliance with EPA guidelines while maintaining performance and safety standards.

In this article, we’ll explore key EPA regulations for A3 refrigerants and how small-diameter copper tubes play a vital role in optimizing system performance, ensuring safety, and achieving regulatory compliance.

Understanding A3 Refrigerants

A3 refrigerants help HVAC/R systems align with current and upcoming environmental regulations

A3 refrigerants are characterized by their low GWP and flammability, making them a sustainable alternative to traditional high-GWP refrigerants. Common examples include propane (R-290) and isobutane (R-600a).

By reducing greenhouse gas emissions, A3 refrigerants help HVAC/R systems align with current and upcoming environmental regulations. Their benefits go beyond regulatory compliance.

energy efficiency

A3 refrigerants improve energy efficiency, enabling systems to operate more effectively while consuming less energy. This dual advantage of sustainability and operational efficiency reduces both carbon footprints and operating costs.

As global regulations continue to phase out high-GWP refrigerants, A3 options stand out as a viable solution that balances environmental responsibility with system performance. Their efficiency and compliance capabilities position A3 refrigerants as a key player in the future of HVAC/R system design.

Advantages of Small-Diameter Copper Tubes

1. Meeting EPA Charge Limits

Small-diameter copper tubes offer a significant advantage in adhering to EPA refrigerant charge limits. With their reduced internal volume, these tubes require less refrigerant to maintain optimal performance.

This feature is particularly beneficial when working with A3 refrigerants, as the EPA enforces strict charge limits to mitigate flammability risks while upholding efficiency.

2. Boosting System Efficiency with Enhanced Heat Transfer

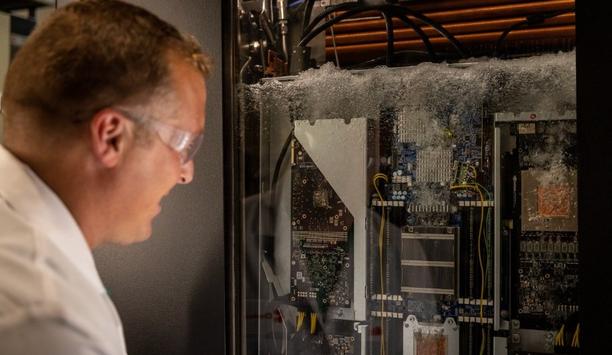

When enhanced with internal grooves, small-diameter copper tubes maximize surface area contact with refrigerants

Copper’s exceptional thermal conductivity, even with smaller tube diameters, ensures effective heat transfer. When enhanced with internal grooves, small-diameter copper tubes maximize surface area contact with refrigerants, further increasing heat transfer efficiency.

This improvement translates to lower energy consumption and reduced operating costs, all while delivering reliable cooling performance.

3. Durability, Safety, and Ease of Installation

Using small-diameter copper tubes reduces the refrigerant charge required within a system, enhancing safety. Copper’s lightweight and flexible properties, especially when annealed, simplify installation, particularly in compact systems with complex configurations.

Its natural corrosion resistance also ensures durability and long-term reliability, minimizing maintenance needs over the equipment’s lifespan.

Innovating for a Sustainable Future

As the HVAC/R industry transitions to A3 refrigerants, adapting to stricter EPA regulations requires innovative system designs that address safety, efficiency, and performance challenges.

Small-diameter copper tubes provide a practical solution by reducing refrigerant charges, enhancing heat transfer, and delivering reliable, durable performance.

reducing environmental impact

These copper innovations are especially valuable for compact, high-performance systems that demand precision and compliance with environmental standards.

By embracing these advancements, the HVAC/R industry can ensure systems are future-ready, capable of meeting evolving regulations while maintaining efficiency and safety. Small-diameter copper tubes are paving the way for a more sustainable HVAC/R landscape, helping businesses succeed in reducing their environmental impact while achieving regulatory compliance.