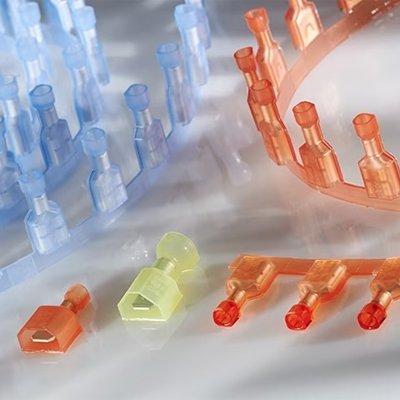

Positive Lock Terminals

Technical Specification

- Make: TE Connectivity

- Model code: Positive Lock Terminals

- Type: Wire-to-Wire, Wire-to-Board

- Wire Size: 26-10 AWG

- Materials / Plating: Base: Brass, Phos. Bronze, Steel ; Plating: Tin, Pre-tin, Silver, Nickel

Positive Lock terminals and housings are differentiated by their low insertion force (LIF) locking receptacles that offer easy assembly and reliable tab mating. The Positive Lock receptacle achieves high retention force while maintaining LIF by securely locking onto a hole in the mating tab. They provide the assembler with an audible and mechanical “snap” when the terminal is correctly seated, ensuring proper assembly - even in hard-to-reach places. The Positive Lock family features multiple series of quick connect terminals, including the ergonomic Mark I series, the Mark II series for value and reliability, and the Mark III series for design flexibility. Applications include appliances, industrial equipment, and automotive.

Read more| Make | TE Connectivity |

|---|---|

| Manufacturer | TE Connectivity |

| Request sample | Click here |

| Category | Components>Terminals and Splices |

| Model code | Positive Lock Terminals |

| Type | Wire-to-Wire, Wire-to-Board |

| Wire Size | 26-10 AWG |

| Materials / Plating | Base: Brass, Phos. Bronze, Steel ; Plating: Tin, Pre-tin, Silver, Nickel |

| Current rating | 24 A |

| Standards/Approvals | UL, VDE, CSA |

| Operating temperature | Standard: 125 °C / High-temp: 250 °C |

| Additional info |

Positive Lock terminals and housings are differentiated by their low insertion force (LIF) locking receptacles that offer easy assembly and reliable tab mating. The Positive Lock receptacle achieves high retention force while maintaining LIF by securely locking onto a hole in the mating tab. They provide the assembler with an audible and mechanical “snap” when the terminal is correctly seated, ensuring proper assembly - even in hard-to-reach places. The Positive Lock family features multiple series of quick connect terminals, including the ergonomic Mark I series, the Mark II series for value and reliability, and the Mark III series for design flexibility. Applications include appliances, industrial equipment, and automotive. |

| Download PDF version Download PDF version | |

More TE Connectivity Terminals and Splices

TE Connectivity white papers

TE Connectivity virtual events

TE Connectivity videos