MAG-MATE Terminals

Technical Specification

- Make: TE Connectivity

- Model code: MAG-MATE Terminals

- Wire Size: Cu: 0.16-2.05 / 34-12 ; Al: 0.18-2.30 / 33-11 mm / AWG

- Max. Number of Wires: 2 per slot

- Type of Wire: Magnet Wire (Cu / Al)

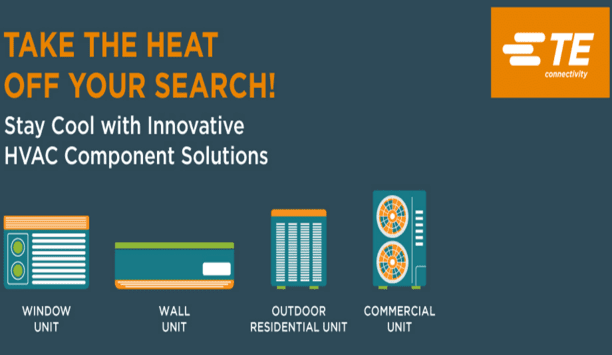

MAG-MATE terminals use insulation displacement contact (IDC) technology for high-speed termination of copper or aluminum magnet wire without wire stripping, soldering or welding. The termination system includes the IDC terminal and a compatible plastic cavity that is either integrated into the coil body or part of a separate housing. MAG-MATE terminals are designed for fully or semi-automated assembly to provide uniform, gas-tight connections at low applied cost. The product line includes many lead wire attachment options, including crimp, poke-in, quick connect tab, solder post, and receptacle. The IDC slot supports up to two magnet wires for splicing. Applications include motor windings, coil connections, and power supplies.

Read more| Make | TE Connectivity |

|---|---|

| Manufacturer | TE Connectivity |

| Request sample | Click here |

| Category | Components>Magnet Wire Connections |

| Model code | MAG-MATE Terminals |

| Wire Size | Cu: 0.16-2.05 / 34-12 ; Al: 0.18-2.30 / 33-11 mm / AWG |

| Max. Number of Wires | 2 per slot |

| Type of Wire | Magnet Wire (Cu / Al) |

| Materials / Plating | Base: Brass, CuNiSi, Phos. Bronze ; Plating: Tin |

| Operating temperature | Max. 150 °C |

| Standards/Approvals | UL |

| Additional info |

MAG-MATE terminals use insulation displacement contact (IDC) technology for high-speed termination of copper or aluminum magnet wire without wire stripping, soldering or welding. The termination system includes the IDC terminal and a compatible plastic cavity that is either integrated into the coil body or part of a separate housing. MAG-MATE terminals are designed for fully or semi-automated assembly to provide uniform, gas-tight connections at low applied cost. The product line includes many lead wire attachment options, including crimp, poke-in, quick connect tab, solder post, and receptacle. The IDC slot supports up to two magnet wires for splicing. Applications include motor windings, coil connections, and power supplies. |

| Download PDF version Download PDF version | |

More TE Connectivity Magnet Wire Connections

TE Connectivity white papers

TE Connectivity virtual events

TE Connectivity videos