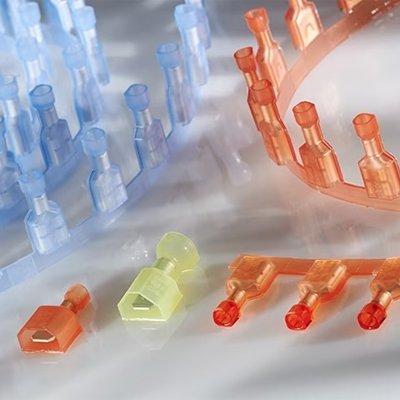

Compact Seal Splice

Technical Specification

- Make: TE Connectivity

- Model code: Compact Seal Splice

- Type: Wire-to-Wire

- Wire Size: 18 ~ 12 AWG

- Materials / Plating: Housing: Polycarbonate ; Contacts: CuNiSi

Compact seal splice creates a robust wire-to-wire connection and protects the connection against harsh environments, including water and UV exposure. The splice features an ergonomic design with an insulation displacement contact (IDC) that provides an easy installation process. The transparent housing allows for visual confirmation of mating status, while color coded connectors reduce the risk of mis-mating. The compact seal splice also delivers design flexibility and safety, with a small size that can be installed in confined spaces and flame-resistant materials that meet UL 94 V-0 and glow wire test (GWT) standards. This product is an excellent solution for harsh environment applications, including air conditioning, outdoor lighting, and indoor wet environments.

Read more| Make | TE Connectivity |

|---|---|

| Manufacturer | TE Connectivity |

| Request sample | Click here |

| Category | Components>Terminals and Splices |

| Model code | Compact Seal Splice |

| Type | Wire-to-Wire |

| Wire Size | 18 ~ 12 AWG |

| Materials / Plating | Housing: Polycarbonate ; Contacts: CuNiSi |

| Current rating | 20 A |

| Standards/Approvals | Meets UL 94 V-0 and glow wire test (GWT) standards |

| Operating temperature | -40 ~ +105 °C |

| Additional info |

Compact seal splice creates a robust wire-to-wire connection and protects the connection against harsh environments, including water and UV exposure. The splice features an ergonomic design with an insulation displacement contact (IDC) that provides an easy installation process. The transparent housing allows for visual confirmation of mating status, while color coded connectors reduce the risk of mis-mating. The compact seal splice also delivers design flexibility and safety, with a small size that can be installed in confined spaces and flame-resistant materials that meet UL 94 V-0 and glow wire test (GWT) standards. This product is an excellent solution for harsh environment applications, including air conditioning, outdoor lighting, and indoor wet environments. |

| Download PDF version Download PDF version | |

More TE Connectivity Terminals and Splices

TE Connectivity white papers

TE Connectivity virtual events

TE Connectivity videos