The energy savings due to the lowering of heating temperatures during unoccupied periods can exceed 20% in the tertiary sector and 30% in the education sector.

When buildings are not occupied continuously, the idling or even the optimized shutdown of heating systems is one of the main sources of energy savings.

heating system consumption

Indeed the heating system consumption matches the thermal loss of heated buildings. When we willingly let the internal temperature drop during a vacant period, these thermal losses lower.

It will certainly be necessary at the end of the idle time to consume energy to bring the building back to temperature. However, as a rule, this consumption will be lower than what would have been necessary with continuous heating, if the reheating is not accompanied by overheating at the end of the reheating process.

energy savings

The energy savings due to the lowering of heating temperatures during periods of vacancy are a function of the inertia, the buildings' insulation, and the vacancy amplitude. In poorly insulated buildings with low or medium inertia, the energy savings from intermittent heating can exceed 20% in the service sector and 30% in the education sector.

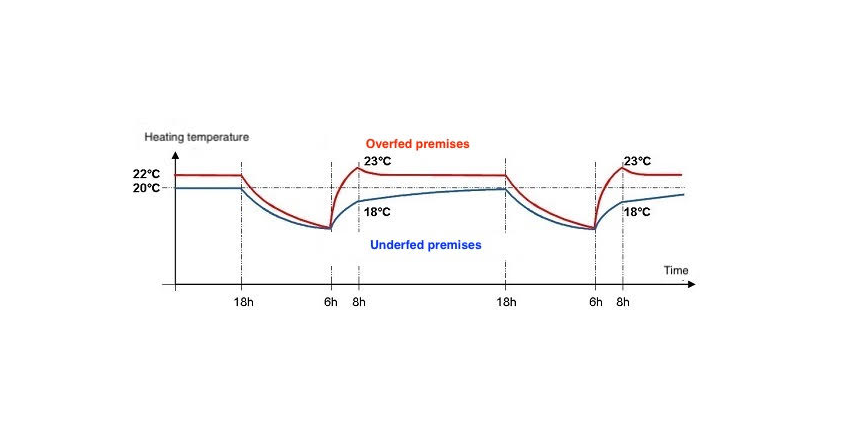

However, when the heating circuits are unbalanced, the temperature recovery is very different in the over- and under-supplied rooms.

Overheating

In the tertiary and education sectors, there is considerable potential for energy savings by lowering temperatures

In unbalanced circuits, after a period of slowing down or switching off the heating, the return to an acceptable temperature in the poorly irrigated zones is accompanied by overheating in the well-irrigated zones and discomfort in the others. Overheating leads to a reduction in energy savings, and in these conditions, on unbalanced circuits, the lowering of the heating during periods of vacancy is very often deliberately limited.

In the tertiary sector and the education sector, there is considerable potential for energy savings by lowering temperatures during periods of non-occupation. The hydraulic balancing of these heating circuits should be a priority.

"balancing" valves

The lack of balance in heating networks is due to a poor distribution of water flows, with some branches being over-supplied while others are poorly irrigated. This can be remedied by the correct setting of so-called "balancing" valves.

When a heating circuit is unbalanced, it is often necessary to overheat the majority of the premises to obtain an acceptable room temperature in the hydraulically disadvantaged zones.

three methods

For the balancing or rebalancing of collective heating installations, three methods are mainly used today.

- Balancing or rebalancing by measuring flow rates

The first method mentioned consists of calculating and adjusting the flows to be conveyed. It requires the presence of "volumetric" valves (which allow the measurement of flow rates), static or dynamic. On existing installations, the determination of the flow rates to be regulated requires the necessary readings to estimate the losses corresponding to each of the antennas of the heating circuit to be treated.

To do this, it is necessary to determine the losses of all the "typical rooms" and in particular those located under the terrace, against the gable, stairwell, etc., and then, which is often very delicate in the absence of a distribution plan, to correctly allocate the corresponding flows to each of the valves to be regulated.

Adjusting flow rates on dynamic valves

Some dynamic valves are directly graduated in flow rate, which facilitates their pre-setting

Balancing by adjusting the flow rates on "dynamic" valves can be done without using any particular method, but their supply must be done with a minimum differential pressure specified by the manufacturer.

Some dynamic valves are directly graduated in flow rate, which facilitates their pre-setting. Nevertheless, whatever the type of these valves, after their presetting, it is very advisable on existing installations to check by measuring the flow rates or the return temperatures the result obtained on each antenna.

Indeed, it is sufficient that, due to significant local clogging, some of them remain disadvantaged to have to overheat all the rest of the distribution.

- Balancing or rebalancing by uniforming return temperatures

The second method is the most recent and is known in France as the "EQUILOG method". As a general rule, with the heating system in operation, the return water temperatures of the antennas to be balanced are standardized so that all the antennas to be regulated are equally "hot". It also allows the adjustment of different return temperatures to make local corrections of the distributed powers.

The procedure, whose principle is old, has been optimized and patented in France and 15 European countries. To date, it has allowed the treatment of more than 200,000 homes on several hundred sites.

Useful for existing installations

This method is particularly suitable for existing installations where the determination of the losses, and therefore of the flow rates to be adjusted, is often very uncertain. It is also the only method to take into account the drop in water temperature during distribution due to heat losses in the pipes, which are more or less well-insulated in older distributions.

The balancing by the uniformity of return temperatures applies to all types of valves, volumetric (which allow the measurement of flow rates) or non-volumetric, whether they are static or dynamic.

- Balancing or rebalancing by hydraulic simulation

The third methodology consists in carrying out a hydraulic simulation of the behavior of the distribution to be balanced. This assumes the availability of precise data on the distribution and the emitters installed. Therefore, this solution is rather intended for new installations on which these data are available, and where the distribution systems do not yet show unpredictable clogging.

Finally, after adjusting the valves according to the results of the simulation, it will be very desirable to check and adjust the result obtained on each valve, either by measuring the flow rates or by measuring the return temperatures of the pipes.